CON1

Q1

CON2

Q2

VDC-

CON4

CON3

L

OUT

400V DC

+

VDC+

CON7

CON6

VSW

CON5

+5V

0V

PWM

INPUT

(J7)

V

DS

I

L

I

SW

V

GL

+6V

0V

V

DS

V

GL

I

L

t0

t1 t2 t3

T

ON1

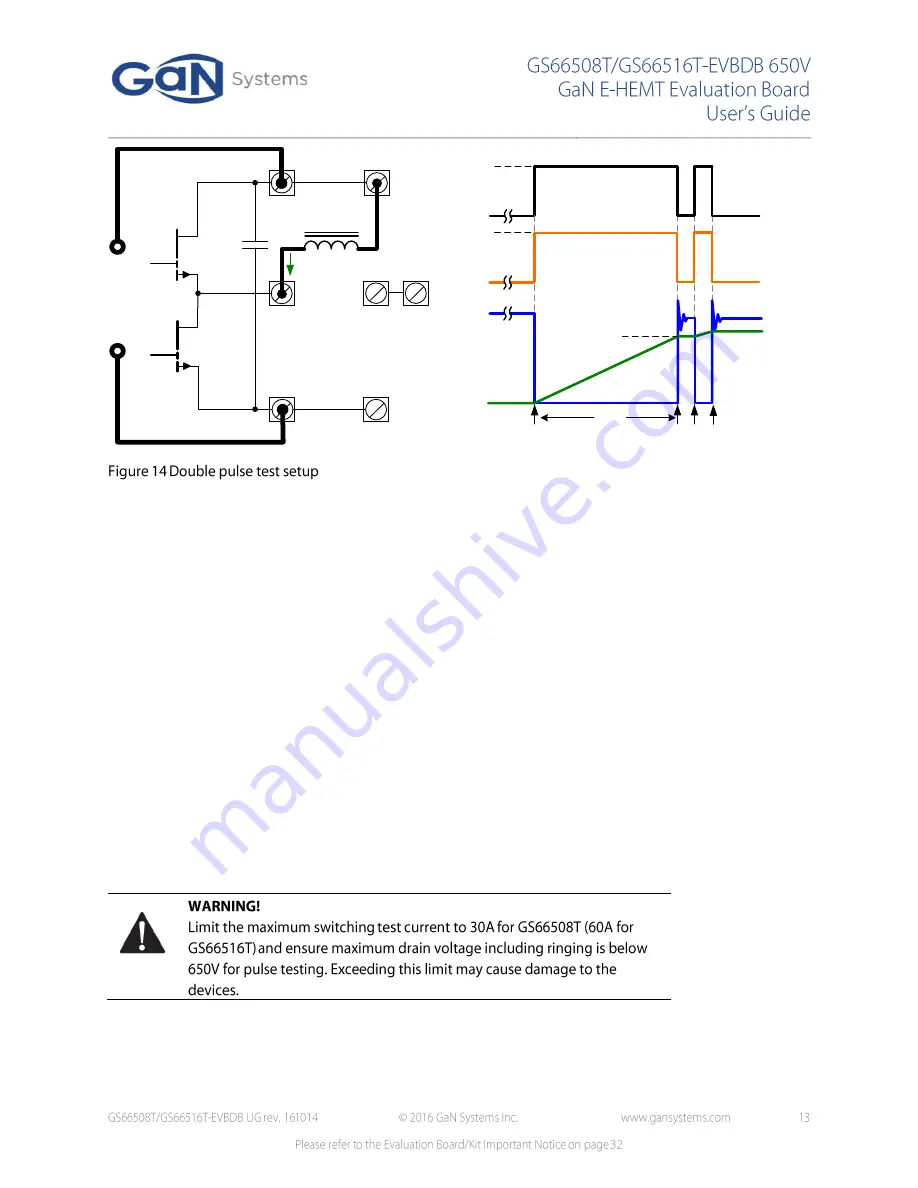

Double pulse test allows easy evaluation of device switching performance at high voltage/current

without the need of actually running at high power. It can also be used for switching loss (Eon/Eoff)

measurement and other switching characterization parameter test.

The circuit configuration and operating principle can be found in Figure 14:

1.

The output inductor is connected to the VDC+.

2.

At t0 when Q2 is switched on, the inductor current starts to ramp up until t1. The period of first

pulse Ton1 defines the switching current I

SW

= (V

DS

*T

ON1

) / L.

3.

t1-t2 is the free wheeling period when the inductor current I

L

forces Q1 to conduct in reverse.

4.

t1 (turn-off) and t2 (turn-on) are of interest for this test as they are the hard switching trasients for

the half bridge circuit when Q2 is under high switching stress.

5.

The second pulse t2-t3 is kept short to limit the peak inductor current at t3.

The double pulse signal can be generated using programmable signal generaotor or microcontroller/DSP

board. As this test involves high switching stress and high current, it is recommended to set the double

pulse test gate signal as single trigger mode or use long repetition period (for example >50-100ms) to void

excess stress to the switches. Q1 can be kept off during the test or driven synchronously (J4 set to OFF or

INT_INV) and Q2 is set to INT (or EXT position if PWM signal is from J5).

Summary of Contents for GS66502B-EVBDB

Page 9: ...GaNPX T GaNPX T FR4 PCB Heatsink M3 Screw Lock Washter Insulated bushing TIM...

Page 17: ......

Page 23: ......

Page 25: ......

Page 26: ...Top Layer Mid Layer 1 Mid Layer 2 Bottom Layer...

Page 29: ...Assembly Top Assembly Bottom...

Page 32: ......