12

MAINTENANCE and ADJUSTMENTS

String Clamp Base Adjustment

The string clamp bases do not require ad-

justment. The simple “Lever Bolt & Nut”

design, provides maximum flexibility for pro-

viding clamping pressure to the turntable

and running clearance for repositioning.

Approximately 1/2 turn is all that is need to

lock and release the clamp base from the

turntable.

NOTE: Do not attempt to adjust the clamp

with the attachement nut on the underside of

the clamp base.

Adjusting the String Clamp Jaw Spacing

The string clamps will need minor adjustments according

to what string type, construction, and gauge you are

using.

To adjust the gap (clamping pressure) between the clamp

jaws, insert the string through the racquet as if you were

beginning the main strings. Clamp the strings and pull

tension. If the string slips through the jaws of the clamp,

tighten the clamp by compressing the clamp jaws to-

gether by hand while turning the Adjustment Knob, in the

clockwise direction. If the clamp leaves impressions or

damages the string, it may be excessively tight and

should be adjusted by turning the Adjustment Knob

counter clockwise to open the gap between the jaws. The clamp jaws should be cleaned

periodically to be free from dirt, oil, and any string coating for them to grip properly. Knife

sharpening stones are excellent for removing build-up on the diamond coated surfaces and

are available.

Note

: The string clamps supplied with your stringing machine can accomodate tight string

patterns such as badminton. Depending on the string pattern, the clamp may spread the

strings slightly which will not compromise the quality of the string job. String clamps specifically

designed for badminton racquets are also available.

Adjustment

Knob

Open Position

Closed Position

Turntable Bushing Adjustment

The turntable bushing is adjusted at the

factory for optimum performance. After time

and use, the turntable bushings may need

minor adjustment. An adjustment is indi-

cated when noticeable turntable looseness

or wobble occurs while stringing.

To adjust the fit between the turntable pin

and the bushings, tighten the set screw at

the top of the bushing using a 3mm hex

wrench. Tighten until the turntable rotates

smoothly without excessive free play.

Summary of Contents for X-Stringer

Page 17: ...16 NOTES...

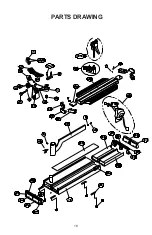

Page 19: ...18 PARTS DRAWING...