9

Prepare Installation Space

en-us

Prepare Installation Space

Prepare Installation Space

The kitchen unit must be heat-resistant to at least

200° F (90°C). The stability of the unit must be

maintained after producing the cut-out.

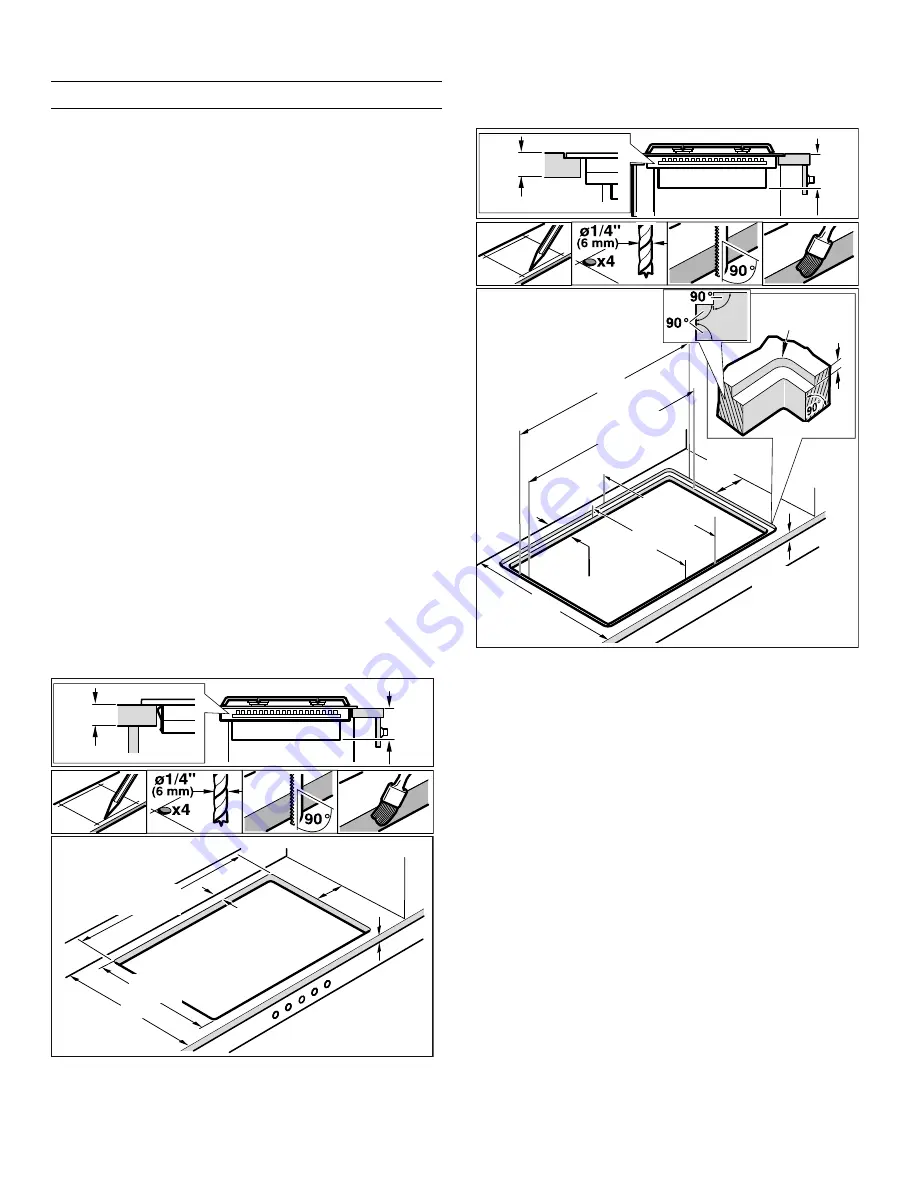

Produce the cut-out in the countertop for one or more

Vario appliances as shown in the installation sketch. The

angle between the cut surface and the countertop must

be 90°.

The cut edges at the sides must be flat to ensure a good

fit of the retaining springs on the appliance. In laminated

worktops, it may be necessary to fit strips at the sides of

the cut-out.

Remove shavings after cutting. Seal cut surfaces for

resistance to heat and so they are watertight.

Pay attention to a minimum gap of 3/8“ (10 mm) from the

underside of the appliance to kitchen units.

Use suitable base constructions to ensure load-carrying

capacity and stability, especially in the case of thin

countertops. Pay attention to the weight of the appliance,

including any payload. Reinforcement material used must

be resistant to heat and moisture.

Note:

Wait until the appliance has been installed in the

installation opening before checking that it is level.

Cutting out countertop

Flush mounting:

Flush mounting into a countertop is

possible.

Flush installation:

The appliance can be installed in the

following temperature- and water-resistant countertops:

▯

Stone countertops

▯

Plastic countertops (such as Corian®)

▯

Solid wood countertops: Only in consultation with the

manufacturer of the countertop (seal cut-out edges)

▯

Installation in other countertops only in consultation

with the manufacturer of the countertop.

Installation in countertops made of particleboard is not

possible.

Note:

Any cut-out work on the countertop must be

performed in a workshop according to the installation

diagram. The cut-out must be made cleanly and precisely

since the cut-out edge is visible on the surface. Clean

and degrease the cut-out edges with a suitable cleaning

agent (bear in mind silicone manufacturer's processing

instructions).

PLQ

PLQ

PLQ

PLQ

PLQ

PP

34

15/16

"

±1/16

PLQ

U

PLQ

PLQ

35

15/16

"

PLQ

±1/16

34

15/16

"

PP

±1/16

PLQ

Summary of Contents for VG491211CA

Page 51: ......