B

B

X

X

/

/

B

B

X

X

G

G

-

-

1

1

0

0

0

0

0

0

S

S

e

e

r

r

i

i

e

e

s

s

G

G

r

r

o

o

o

o

v

v

e

e

M

M

e

e

a

a

s

s

u

u

r

r

e

e

m

m

e

e

n

n

t

t

G

G

a

a

g

g

e

e

O

O

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

M

M

a

a

n

n

u

u

a

a

l

l

29

Operating Procedures

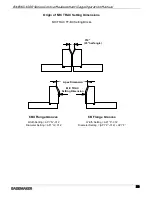

Inspecting Parts with the BXG-1000 Gage

Materials Needed:

•

BXG-1000 gage

•

Inspection report

•

Part

1. After zeroing the BXG-1000 gage, position the

gage on the flange face and into the ring

groove of the part, as shown.

2. While maintaining pressure against the rear

contact point and flange face, sweep the gage

back and forth, using the rear contact point as

a pivot, to locate the smallest indicator

reading.

Note:

Be sure that the small revolution counter

on the indicator is pointing to the same

number as when the gage was zeroed.

Refer to the number previously recorded

on the side of the gage.

3. Repeat the process in several locations

around the groove to get an average groove

width and record the information on an

inspection report.

Note:

Refer to the 6B & 6BX Groove Inspection

Tolerances table in this manual for the

allowable groove width variation.

4. Use the first part you inspected as a control

piece to verify repeatability. Mark the part at a

location where it was inspected and record the

deviation from zero.

5.

During the inspection process, periodically

place the BXG-1000 on the control piece to

verify the gage’s accuracy.