7

Governors America Corp. © 2020 Copyright All Rights Reserved

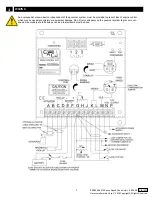

ESD5550-5570 Series Speed Control Unit

9-2020-E

PIB1003

6

METHODS OF OPERATION

One of two methods of operation for the ESD5550/5570 may now selected; starting at operating speed, or starting at idle.

1. Remove the connection between Terminals M & G.

2. Start the engine and accelerate directly to the operating

speed (Gen Sets, etc.).

3. Adjust the SPEED RAMPING for the least smoke on acceler-

ation from idle to rated speed.

4. If the starting smoke is excessive, the STARTING FuEL may

need to be adjusted slightly CCW.

5. If the starting time is too long, the STARTING FuEL may need

to be adjusted slightly CW.

This method separates the starting process so that each may be

optimized for the lowest smoke emissions.

1. Replace the connection between Terminals M & G with a

switch, usually an oil pressure switch.

2. Start the engine and control at an idle speed for a period of

time prior to accelerating to the operating speed.

3. If the starting smoke is excessive, the STARTING FuEL may

need to be adjusted slightly CCW.

4. If the starting time is too long, the STARTING FuEL may need

to be adjusted slightly CW.

5. When the switch opens, adjust the SPEED RAMPING for the

least amount of smoke when accelerating from idle speed to

rated speed.

STarTInG aT oPeraTInG SPeeD

STarTInG aT IDLe SPeeD

7

SySTEM TROUblESHOOTINg

InSUffIcIenT maGneTIc SPeeD SIGnaL

A strong magnetic speed sensor signal eliminates the possibility of missed or extra pulses. The speed control unit governs well with 0.5

volts RMS speed sensor signal.

A speed sensor signal of 3 volts RMS or greater at governed speed is recommended. Measurement of the signal is made at Terminals

C and D.

The amplitude of the speed sensor signal can be raised by reducing the gap between the speed sensor tip and the engine ring gear. The

gap should not be any smaller than 0.02 in (0.5 mm). When the engine is stopped, back the speed sensor out by 3/4 turn after touching

the ring gear tooth to achieve a satisfactory air gap.

SYSTem InoPeraTIve

If the engine governing system does not function, the fault may be determined by performing the voltage tests described in Steps 1

through 4. Positive (+) and negative (-) refer to meter polarity. Should normal values be indicated during troubleshooting steps, and then

the fault may be with the actuator or the wiring to the actuator. Tests are performed with battery power on and the engine off, except where

noted. See your actuator publication for troubleshooting testing.

STeP

WIreS

cHecK

ProBaBLe caUSe

1

F(+) & E(-)

Battery Supply

Voltage

(12 or 24 V DC)

1. DC battery power not connected. Check for blown fuse.

2. Low battery voltage

3. Wiring error

2

C(+) & D(-)

1.0 V AC RMS

minimum while

cranking

1. Gap between speed sensor and gear teeth too great. Check Gap.

2. Improper or defective wiring to the speed sensor. Resistance between D and C should be 160 to

1200 Ω. See specific mag pickup data for resistance.

3. Defective speed sensor.

3

P(+) & G(-)

10 V DC, Internal

Supply

1. Short on Terminal P.

2. Defective speed control unit.

4

F(+) & A(-)

1.0 - 2.0 V DC while

cranking

1. SPEED parameter set too low

2. Short/open in actuator wiring

3. Defective speed control

4. Defective actuator, see your actuator’s Troubleshooting guide.