7

12

1

6

5

3

2

9

10

4

7

8

11

13

14

15

16

17

18

19

20

21

22

23

22

24

Device

Hose reel

Interval

Daily

Every three

months

Every six

months

Item

1.1

1.2

1.3

1.4

1.5

Inspection module

Hose

Hose connections

Hose reel

Duct system

Hose reel

Maintenance instructions

Check that the hose is intact. Replace if necessary.

Check the fastening on hose connections.

Look for leaks, damage and wear.

Check the dust build-up and clean if necessary.

Clean the roller externally with a damp cloth.

Date

6.3 Maintenance

6.3.1 Checklist maintenance

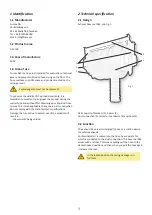

7 Details diagram

1. Shaft extension

2. Spring pile

3. Spacing sleeve

4. Bracket

5. Bearing retainer

6.

Guide bearing

7. Locking mechanism

8.

Slide bearings

9. Beam

10. Bracket

11.

Connection

12.

Ratchet disc

13. End cap

14. Drum

15.

Guard

16. Steering hose

17. Bracket

18. Suction tube

19. Threaded rod

20. Hose clamp**

21. End cap

22. Hose clamp**

23. Protective cloth**

24. Hose*

*

Accessories AGX hose

**

Accessories AES 200