5

1

(h)

ASE 130

8

33

9

ASE 130

8

41

11

ASE 130

8

49

12

(h)

6

5

7

3

4

2

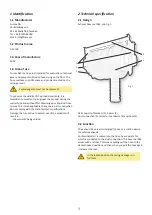

Fig. 4

Fig. 5

Fig. 3

3 Preparation for use

3.1 Transport and storage

Protect the hose reel from rain, snow

aggressive

atmospheres and other damaging circuimstances.

3.2

Installation and assembly

3.2.1 Assembly

Assembly may only be carried out under consideration of

these assembly instructions and applicable regulations.

1. Remove all the packaging from the product and leave it

assembled on the pallet.

Item 2-6 does not apply if the reel has been

ordered complete with hose.

When assembling the hose, ensure that the reel

is blocked correctly. Risk of personal injury.

2. Secure the pallet and pre-load the hose reel according

to the table. Turn the drum in the direction indicated by

the arrow (1, Fig. 3).

3. Remove the hose clamp (2) and rubber sheet (3).

4. Install the hose (5) on the suction tube (4) using hose

clamps (6).

5.

Secure the hose by first placing the rubber cloth (3)

around

the hose. Then pull the hose clip (2) through the holes

and around the rubber sheet to lock securely (Fig. 4)

.

The hose stop should, when in the retracted

position, rest against the drum and fit between

the end cap and the adjacent hose. Risk of wear.

6. Install the hose stop (7, Fig. 3) in the desired position.

Release the latch and wind the hose until it stops against

the hose stop.Check that the hose stop is working and

assembled correctly.

7. Remove the roller from the pallet and install it onto the

ceiling or wall using correctly dimensioned fastening

elements.

Dim.

Hose length

Bias

Product

(mm)

(m)

(turns)*

*

The calculations only apply when using Fumex original AGX hose,

Fumex 3.2 kg nozzle and an installation height of 6 metres.

8. Check the roller and the ventilation ducts properly, so

that foreign objects are not present. Remove any such

objects immediately.

9. Seal and install the ventilation ducts directly to the

duct connection on the roller, or use a hose ASL 200

between the duct and roller (see

Accessories

).

10. Check that the gaskets and connections on the roller

and ventilation duct are tight

.

11. Install the nozzle.

12.

The hose winding reel is ready for use.

Maximum mounting height

- 6 m (h, Fig. 5).