Object Properties:

Object Properties toolbar is used to change the basic properties of graphs, including graph location, size,

scaling, and processing number.

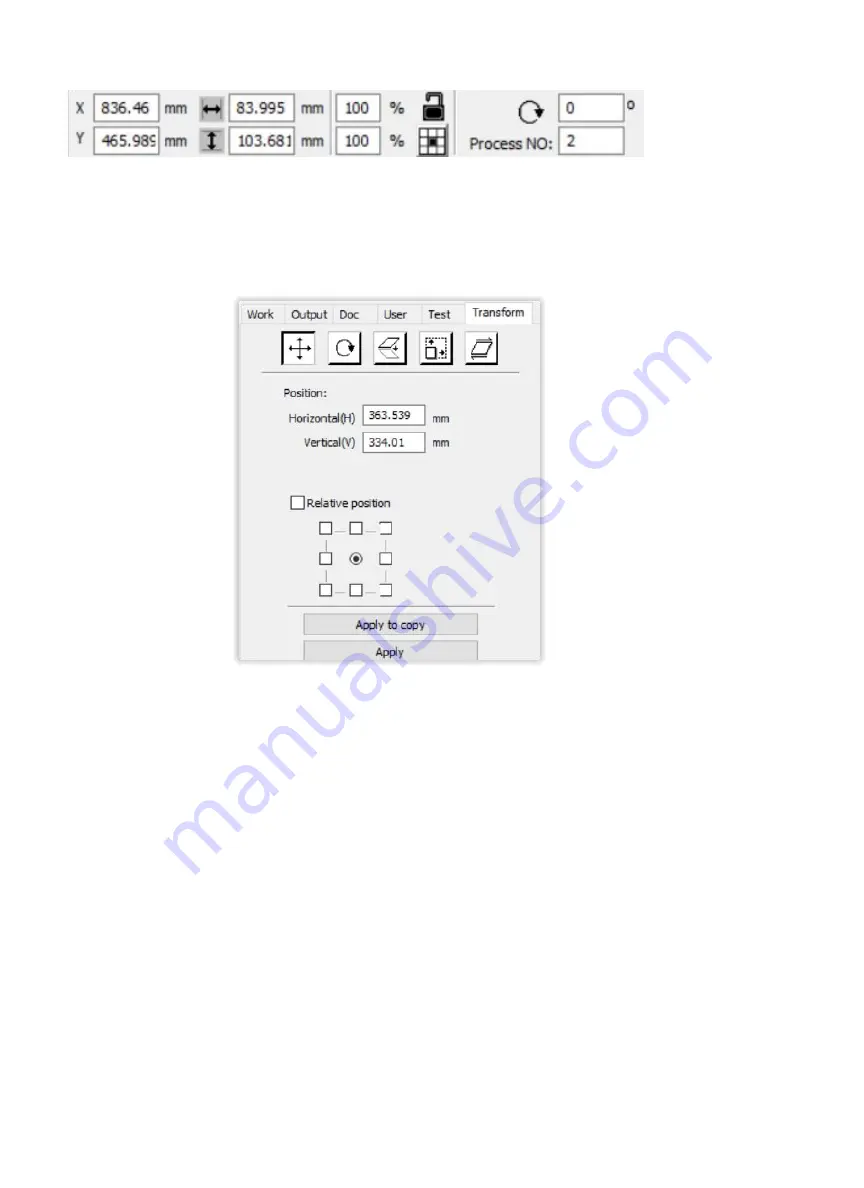

Object Transformation:

In order to perform object transformation, open the transformation window.

Object Properties & Transformation:

The 5 boxes at the top of the transformation windows are:

Object Positioning

- Enables you to move the object

Object Rotation

-Rotates the object the number of degrees selected.

Mirror

-Flips the object vertically and horizontally in different angles

Scaling

-Increase or decrease the size of the object

Skew

-Flips the object horizontally

28

Summary of Contents for Master Class CO2 Flatbed

Page 1: ...Master Class CO2 Flatbed USER MANUAL...

Page 33: ......