22

KNOW YOUR PRODUCT

Advanced blade tracking:

Most tracking adjustments can be done by simply adjusting the top

wheel tracking knob as the lower wheel comes correctly adjusted

from the factory. However there may come a time when adjustment is

necessary such as if the blade keeps falling off the drive wheels.

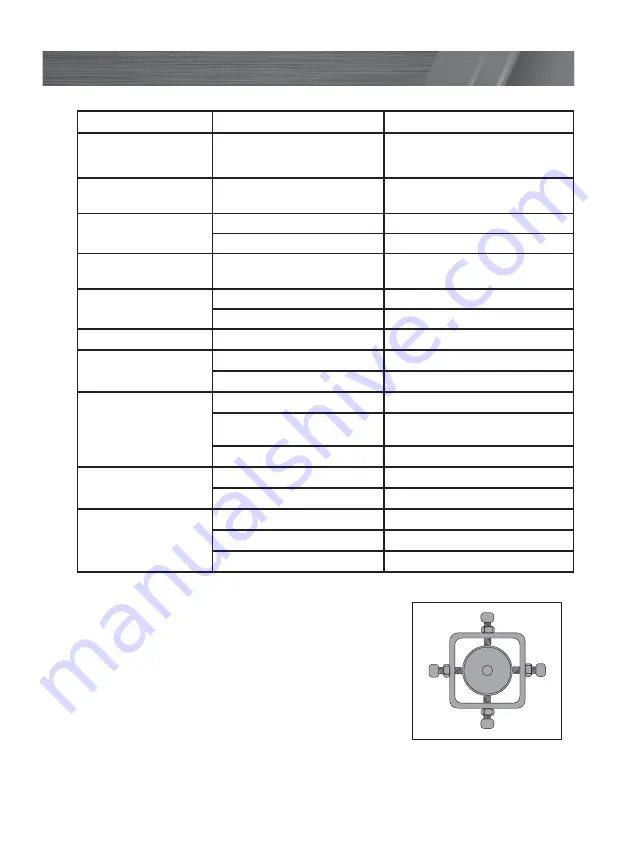

At the back of the unit you will find 4 screws that allows fine

adjustment to the lower pulley tacking. The upper and lower screws

adjust the vertical angle and the left and right screws adjust the

horizontal angle. If the lower wheel tracking is out, only adjust the

upper and lower screws. However if the wheels keep throwing the

blade, you will have to adjust horizontal angle using the left and

right screws. When adjusting the angle ensure you only make small

adjustments, being careful to tighten and loosen in the direction you wish to align. For example,

loosening the left screw then tightening the right screw. This is to ensure there is no movement in

the wheels angle during operation. Be sure all adjustment screws are tight before use and you have

manually spun the wheels by hand to check the alignment.

TROUBLESHOOTING

Problem

Cause

Remedy

Bandsaw is not

working

No power supplied

Make sure the power plug is

connected and power outlet is in

working order

Cannot adjust

tracking

Tracking lock knob is on

Unlock the tracking lock by turning

the tracking lock knob anti-clockwise

Premature and

excessive tooth wear

Feed Pressure too high

Slow down feed rate

Guide hitting teeth alignment

Readjust blade tracking and guides

Finished surface too

rough

Feed rate too high

Slow down feed rate

Premature blade

breakage

Band tension too high

Readjust blade tension

Excessive feed pressure

Slow down feed rate

Cutting rate too slow

Damaged or worn blade

Replace blade

Gullets loaded with

chips

Speed too slow

Use faster speed

Chip brush not working properly

Clean or replace brushes

Belly shaped cuts

Improper blade tension

Readjust blade tension

Guide arm is too far from work

piece

Move guide arm closer to work piece

Excessive feed force

Use less feed force

Band stalls in work

Feed pressure too great

Use less feed force

Improper blade tension

Readjust blade tension

Blade vibration

Guides poorly adjusted

Readjust blade tracking and guides

Blades tension too low

Readjust blade tension

Work piece not properly secured

Secure work piece properly

Summary of Contents for FBBS-750

Page 25: ...25...