3-6

NOTICES

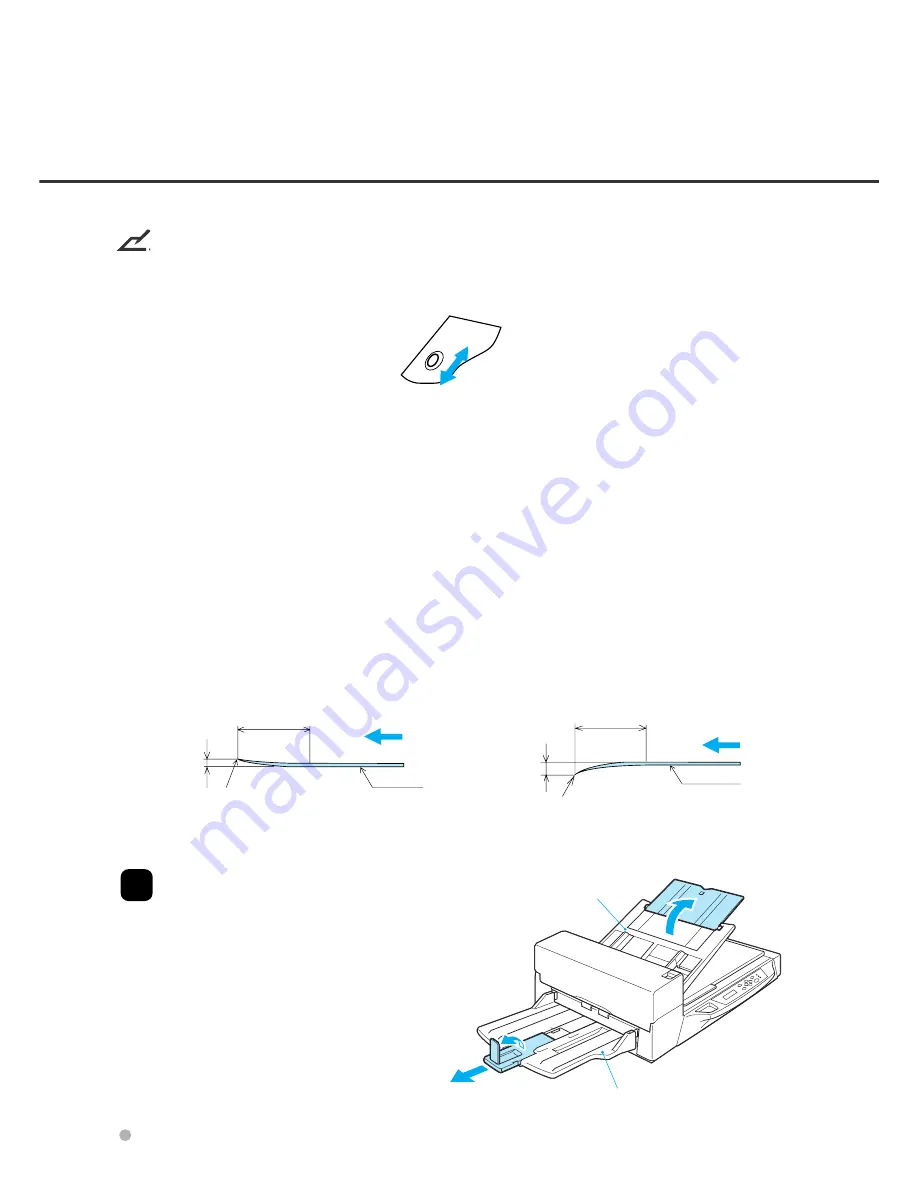

Note the following when preparing the paper.

• Remove paper clips and staples. Flatten the staple holes.

• Read the following documents using the Flatbed:

- Paper with clips or staples.

- Paper written on with wet ink.

- Paper of uneven thickness (for example, envelopes).

- Paper with large rumples or curls.

- Paper with folds or tears.

- Tracing paper.

- Coated paper.

- Carbon paper.

- Paper shorter than A8 (portrait) size or wider than A3 size or 11 x 17 inches.

- Materials other than paper (for example, clothes, sheet metal, or OHP film).

- Photographic paper.

- Paper with perforations on the side.

- Non-rectangular paper.

- Very thin paper.

• Set documents on the ADF so that the curl of the leading edge does not exceed the measures shown

below.

• To avoid skewing, do not feed docments of different widths during the same batch.

3

Adjust the stacker extension to the

paper size, and then flip out the plate.

Less than

5mm

More than 30mm

Top of the paper

Less than

3mm

More than 30mm

Feed direction

Top of the paper

Read surface

Feed direction

Read surface

ADF paper chute

Stacker

Summary of Contents for fi-4640S

Page 1: ...Operator s Guide fi 4640S Image Scanner C150 E209 01EN ...

Page 2: ...fi 4640S Image Scanner Operator sGuide ...

Page 10: ...viii ...

Page 16: ...1 4 Stacker Thumbscrew Guide A ASY Pick roller 2 Pick roller 1 Pad ASY Assemblies ...

Page 23: ...1 11 Image transfer alarm Memory alarm EEPROM alarm FAN alarm IPC Board alarm ...

Page 32: ...2 8 ...

Page 56: ...5 3 unit mm 521 234 335 445 696 17 5 27 4 13 2 9 2 20 5 Dimensions ...

Page 57: ...5 4 ...

Page 89: ...GL 6 ...

Page 92: ......