46

U41169-J-Z156-4-74

Fitting/Removing Drive/Blank Insert

SCSI Drives

Installing the hard disk units

V

CAUTION!

The hard disk unit must be acclimatized in its operating environment for

an acclimatization time.

Ê

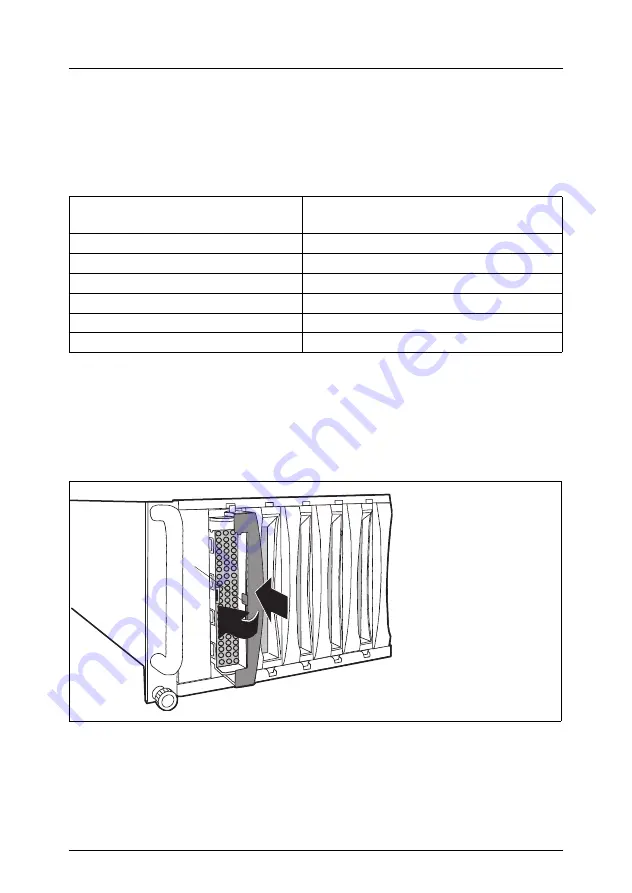

Solve the locking mechanism by pressing the locking button (1) (see

) (only for a part of subsystems).

Ê

Push the handle of the hard disk unit fully in the direction of the arrow.

Figure 19: Installing the Hard Disk Unit

Ê

Push the hard disk unit into the empty slot (1) until it stops.

Ê

Push the unit handle completely in the direction of the arrow (2) until the

locking mechanism (3) engages.

Temperature difference (°C)

(operating environment/outside)

Minimum acclimatization time

(hours)

5

3

10

5

15

7

20

8

25

9

30

10

Table 8: Acclimatization Time for the Hard Disk Drives

!