70S+A_Rev1

65

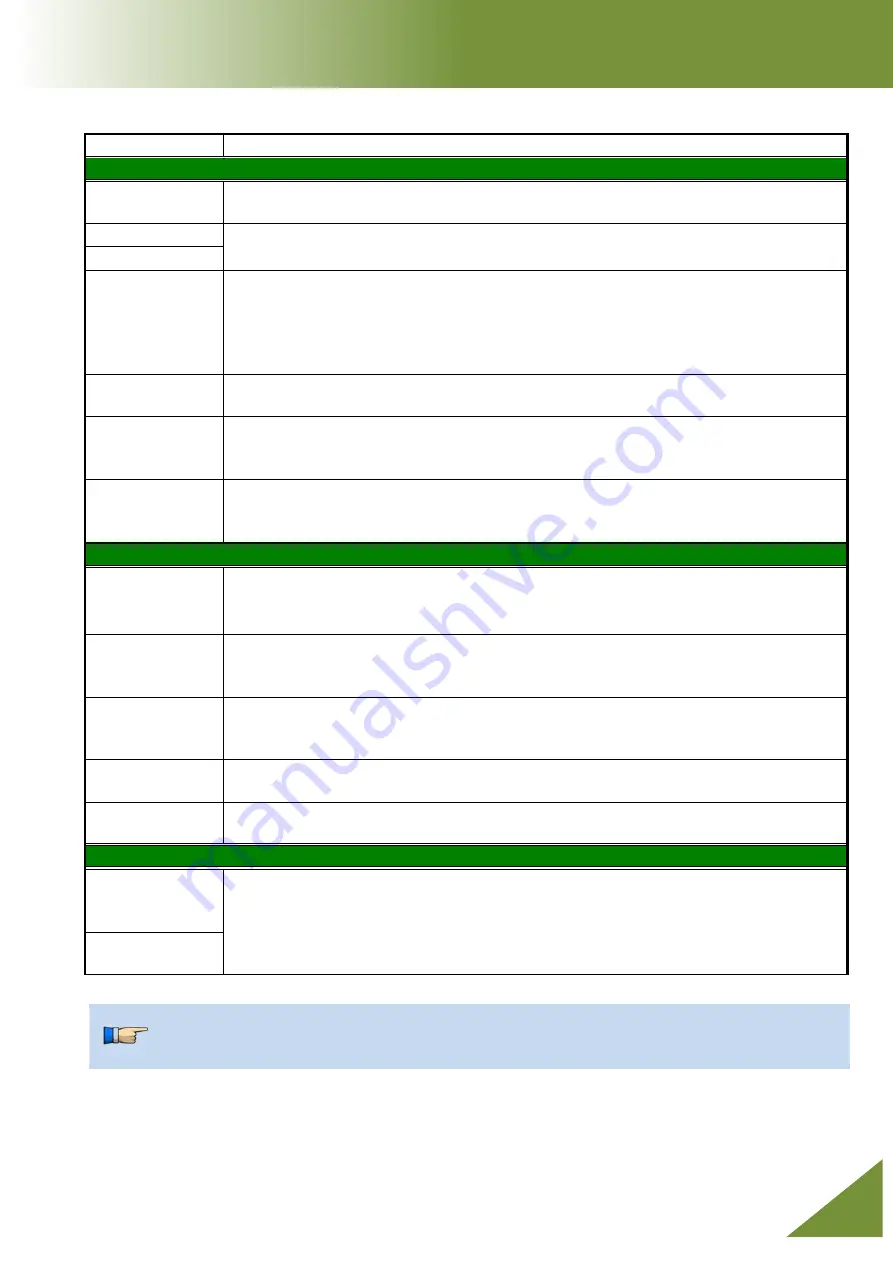

Splice Menu

A continuation of

edit parameter list

Parameter

Description

Estimation

Estimating

Mode

Selects splice loss estimation to "OFF" ”Clad” ”Core” ”Core-Fine”

MFD-Left

Sets MFD of the fibers. This MFD value is taken into account for estimating

splice loss.

MFD-Right

Minimum Loss

This amount is added to the estimated splice loss originally calculated. When

splicing specialty or dissimilar fibers, a high actual splice loss may occur even

with optimized arc conditions. To make the actual splice loss concur with the

estimated splice loss, set the minimum value of estimate to the minimum

optimized actual splice loss.

Wave Length

Sets the wave length. This value is taken into account for estimating splice

loss.

Core Bending

Coef.

Determines how Core bending ( core step / core curve ) influences splice loss

estimation. If “Estimating Mode” is set “OFF” or “CLAD,” Core bending is

automatically set “OFF.”

MFD Mismatch

Coef.

Determines how MFD mismatch influences splice loss estimation.

If “Estimating Mode” is set “OFF” or “CLAD,” MFD mismatch is automatically

set “OFF.”

Error Limit

Cleave Angle

Limit

An error message is displayed if the cleave angle of either the left or right

fiber ends exceeds the selected threshold (cleave limit).

“OFF”: Does not make judgment on cleave angle.

Cleave Shape

Error

Error message is displayed if the cleaved end face of either left or right fiber

exceeds the selected threshold (cleave shape).

“OFF”: Does not make judgment on cleave shape.

Fiber Angle

Limit

An error message is displayed if the bend angle of the two fibers spliced

exceeds the selected threshold (Fiber Angle Limit).

“OFF”: Does not make judgment on fiber angle.

Loss Limit

An error message is displayed if the estimated splice loss exceeds selected

threshold (loss limit).

Bubble

Sensitivity

An error message is displayed if the bubble of fiber exceeds the selected

threshold (bubble).

Stripper

Heat

Temperature

Level

These are stripper parameters. They are automatically sent to the stripper if

[Heater Parameter Control] in “Stripper Setting” menu is set to “Splice Mode”.

See the detail in “Bluetooth” section.

Heat Finish

Time

Menus change when [Select Splice Mode] is set to [SM AUTO], [NZ AUTO], [DS

AUTO] and [MM AUTO] mode.