26

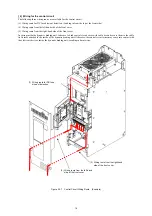

5.3 Periodic Inspection

Periodical inspection must be performed after stopping operations, turning off the power supply, and removing the front

cover.

Even if the power has been shut down, it takes the time for the DC link bus capacitor to discharge. After the charging lamp is turned OFF,

therefore, make sure for safety that the DC link bus voltage has dropped to the safe level (+25 VDC or below) using a multimeter or a

similar instrument.

Table 7.3-1 Periodic Inspection List 1

Check part

Check item

How to inspect

Evaluation criteria

Structural

components

such as chassis

and covers of the

cabinet and the

dynamic

breaking unit

Check for:

1) Loose bolts (at clamp sections).

2) Deformation and breakage (warped

cabinet)

3) Discoloration caused by overheat

4) Contamination and accumulation of

dust or dirt

1) Retighten.

2), 3), 4)

Visual

inspection

1), 2), 3), 4)

No

abnormalities

(If any section is stained,

clean it with a soft

cloth.)

Common

1) Check that bolts and screws are tight

and not missing.

2) Check the devices and insulators for

deformation, cracks, breakage and

discoloration caused by overheat or

deterioration.

3) Check for contamination or

accumulation of dust or dirt.

1) Retighten.

2), 3)

Visual

inspection

1), 2), 3)

No

abnormalities

(If any section is stained,

clean it with a soft

cloth.)

Conductors

and wires

1) Check conductors for discoloration

and distortion caused by overheat.

2) Check the sheath of the wires for

cracks and discoloration.

1), 2)

Visual

inspection

1), 2)

No

abnormalities

Terminal

blocks

Check that the terminal blocks are not

damaged.

Visual inspection

No abnormalities

Main c

ircui

t

DC link bus

capacitor

1) Check for electrolyte leakage,

discoloration, cracks and swelling of

the casing.

2) Check that the safety valve does not

protrude remarkably.

1), 2)

Visual

inspection

1), 2)

No

abnormalities

Control circu

it

Printed

circuit

board

1) Check for loose screws and

connectors.

2) Check for odor and discoloration.

3) Check for cracks, breakage,

deformation and remarkable rust.

4) Check the capacitors for electrolyte

leaks and deformation.

1) Retighten.

2) Olfactory and visual

inspection

3), 4)

Visual

inspection

1), 2), 3), 4)

No

abnormalities

Cooling fan 1) Check for any abnormality.

2) Check for loose bolts.

3) Check for discoloration caused by

overheat.

1) Turn by hand. (Be sure to

turn the power OFF

beforehand.)

2) Retighten.

3) Visual inspection

1) Smooth rotation

2), 3)

No

abnormalities

Cooling system

Ventilation

path

Check the heat sink, intake and exhaust

ports for clogging and foreign materials.

Visual inspection

No clogging or

accumulation of dust, dirt

or foreign materials.

Clean it, if any, with a

vacuum cleaner.

Additional notes

(1) The inspection interval (every year) of check items is merely a guide. Make the interval shorter depending on the

installation environment.

(2) Store and organize the inspection results to utilize them as a guide for operation and maintenance of the equipment and

service life estimation.

(3) The dynamic breaking unit has cooling fans inside to ventilate itself for discharging the heat generated by the power

converter section. This will accumulate dust or dirt on the heat sink depending on the surrounding environment.

In a dusty environment, the heat sink requires cleaning in a shorter interval than that specified in periodic inspection.

Neglecting cleaning of the heat sink can rise its temperature, activating protective circuits to lead to an abrupt shutdown

or causing the temperature rise of the surrounding electronic devices to adversely affect their service life.

Summary of Contents for BUC S-69D

Page 8: ......