7

condensate

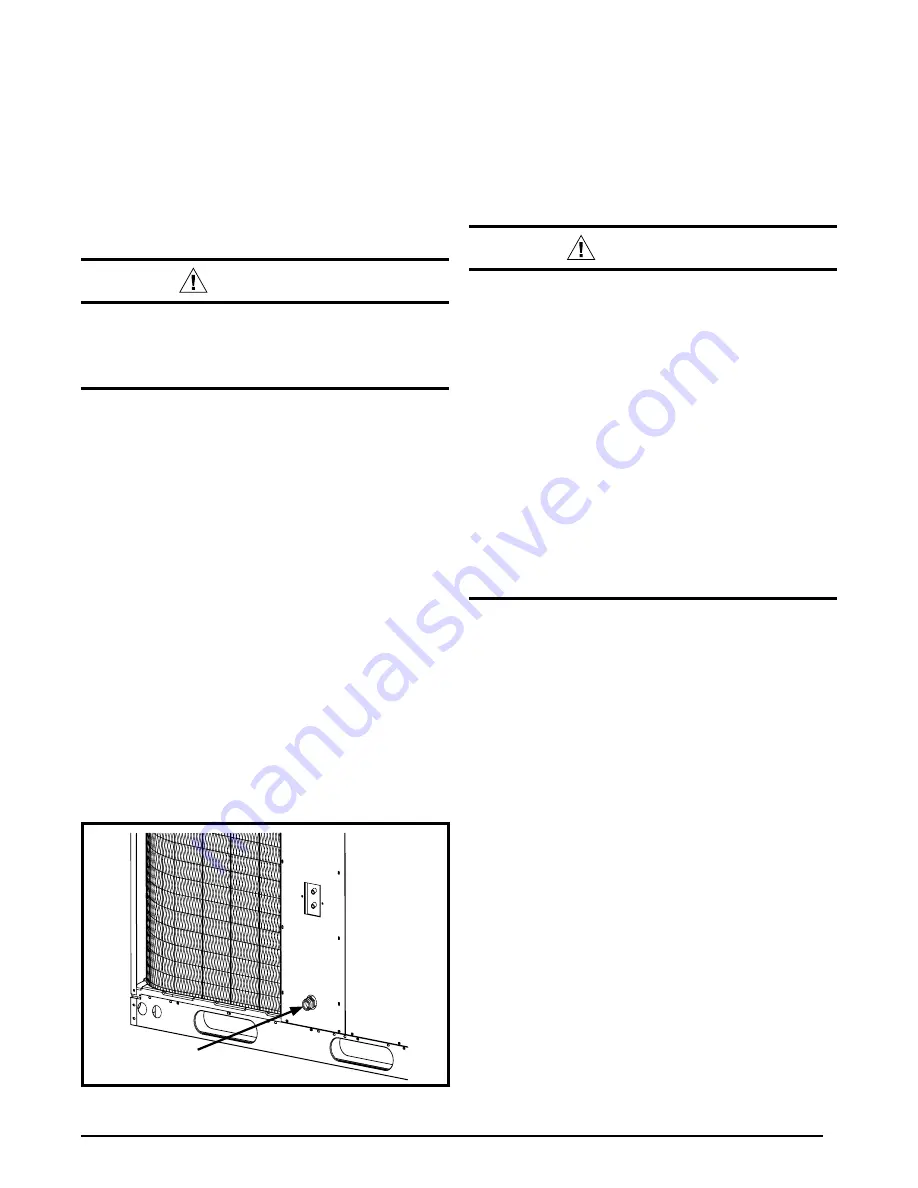

Drain

Figure 3. condensate Drain location

•

Duct lining must be UL classified batts or blankets with

a fire hazard classification of FHC-25/50 or less.

•

Fiber duct work may be used in place of internal duct

liners if the fiber duct work is in accordance with the

current revision of the SMACNA construction standard

on fibrous glass ducts. Fibrous duct work and internal

acoustical lining must be NFPA Class 1 air ducts when

tested per UL Standard 181 for Class 1 ducts.

air Filter Requirements

waRning:

never operate the unit without a filter in place.

Dust and lint could accumulate on internal parts,

resulting in loss of efficiency, equipment damage

and possible fire.

•

This unit is not supplied with air filter(s) and has no

factory equipped means for accomodating internal

filter(s). A suitable air filter must be installed upstream

of the evaporator coil of the return air system.

•

All return air must pass through the filters before entering

the evaporator coil.

It is important that all filters be

kept clean and replaced frequently to ensure proper

operation of unit. Dirty or clogged filters will reduce the

efficiency of the unit and result in unit shutdowns.

•

Air filter pressure drop must not exceed 0.08 inches WC.

• Downflow Installations require an internal filter

accessory kit to be installed.

• Horizontal Installations require the air filter system be

installed in the return air ductwork.

condensate Drain

Condensate is removed from the unit through the 3/4”

female pipe fitting located on the front side of the unit

(See Figure 3). Install a 2 inch condensate trap in the

drain line of the same size and prime with water. When

connecting rigid drain line, hold the female fitting with a

wrench to prevent twisting. Do not over tighten! Refer

to local codes and restrictions for proper condensate

disposal requirements.

HeaT PumP inSTallaTion

Packaging Removal

Remove the shipping carton and User’s Manual from the

equipment. Take care not to damage the tubing connections

when removing the carton. For rooftop installations, remove

and discard the two supports attached beneath the unit.

Rigging and Hoisting

waRning:

To avoid the risk of property damage, personal

injury, or death, it is the rigger’s responsibility

to ensure that whatever means are used to hoist

the unit are safe and adequate:

•

The lifting equipment must be adequate for the

load. Refer to Table 7 (page 16) for unit weights.

•

The unit must be lifted from the holes in the

base rails using cables or chains.

•

Spreader bars are required to protect the unit

and ensure even loading.

•

keep the unit in an upright position at all times.

The rigging must be located outside the units

center of gravity. Refer to Figure 9 (page 16)

for locating the center of gravity.

•

all panels must be securely in place during

rigging and hoisting.

minimum clearance Requirements

Q4SE units are certified as combination heating and

cooling equipment for outdoor rooftop or ground level

installations. Figure 2 (page 6) displays the minimum

clearances to obstructions for both Downflow and

Horizontal discharge.

Units may be installed on Class A, B, or C roof covering

material when used with bottom supply and return air

ducts as long as the following requirements are met:

• If using vertical supply and return air ducts, a roof curb

must be installed prior to unit installation. See Rigging

and Hoisting section for setting of the unit.

Horizontal to Downflow conversion

The unit is shipped ready for horizontal duct connections.

If down flow ducts are required, the unit must be converted

following the steps below for both the supply and return

ducts.

1. Remove the horizontal duct cap.

2. Locate the duct cap inside the duct openings and

remove the screw holding it in place.

3. Lift the cap out of the unit. (Hint: The cap can be

pushed up from the bottom by reaching through the

fork slot).

4. Cover the horizontal duct opening with the horizontal

duct cap. The insulation will be on the indoor side.

5. Fasten the cover with screws to seal.