DF4000 Rev0204

16

OPERATION

On power-up the flowmeter will be in the normal operating mode. Flow rate

information from a flow sensor or from the datalink interface is processed and displayed.

Operator input is necessary only when using the totalizing function or accessing

program information.

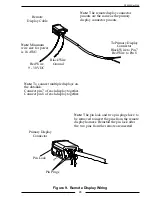

Datalink Interface

The FRC datalink interface is standard on all flowmeters and provides a way of

connecting multiple display modules on a shared data bus. The DF4000 (digital

flowmeter) and FP4000 (pressure gauge/flowmeter) series display modules can operate

as independent displays or they can be interconnected to provide remote displays, the

display of flow through multiple discharges (summing), and the display of total flow

for multiple discharges (accumulation). (Refer to Figure 6.)

Primary Display Module

Primary displays are programmed with the module function

Pri

. A primary display

receives input from the pressure transducer and flow sensor. When it is programmed

with Id 0 it will not output information on to the datalink. When it is programmed

with Id 1 to Id 99, it will provide information (via the datalink) to remote, summing,

and accumulator displays.

Remote Display Module

Remote displays are programmed with the module function

SLA

(slaved to a

primary). A remote display must be programmed with the same ID number as a primary

display. It will receive information for the display of flow rate from the primary display

over the datalink. All program code features are programmed independently of the

primary display. No calibration is necessary on a remote display.

Summing Display Module

Summing displays are programmed with the module function

SU

. A summing

display will show the actual flow rate for all primary displays on the datalink except

for those with Id 0.

Accumulator Display Module

Accumulator displays are programmed with the module function

ACC

. An

accumulator display will show total accumulated flow for all primary displays on the

datalink except for those with Id 0. The number shown in the display will be x 100

scale.

Note:

A single display module can be used for both summing and

accumulation. Program it as a summing display, when the

TOTAL

button

is pressed it will show total accumulated flow for all primary displays on

the datalink.