3

TEST RUNNING

If test running pump before installation:

1. Ensure that the power supply corresponds with that shown

on the nameplate of the motor.

2. Install pump and components appropriate for the test.

3. Make sure power supply is turned off and circuit breaker

or disconnect switch is open. Make electrical connections

appropriate to your motor as shown in Figure 2.

4. Run pump and motor unit for a few seconds to ensure that it

is in working order.

SUITABILITY OF WATER SOURCE

Water from an undeveloped source often contains an excessive

amount of sand, dirt, and abrasives which can damage the

pump. Make arrangements to ensure an adequate

fl

ow of water

over the motor for cooling purposes. Determine the correct

pump setting by taking into account the static water level and

the drawdown at the proposed pumping rate.

DROP PIPE

Galvanized pipe is recommended for suspending submersible

pumps. Plastic pipe may be used only when observing the

manufacturer’s recommendations of depth and pressure.

Consider installing a safety cable to prevent losing the pump if

the pipe should break.

Schedule 40 galvanized pipe is a suitable drop pipe.

Take great care to keep pipes clean and free from pebbles,

scale, and thread chips. Make sound, air-tight connections at all

fi

ttings. Pipe sealant is recommended.

CHECK VALVES

Many pumps have a built-in or externally supplied check valve.

For a pump without one, install a check valve immediately

above the pump. Install an additional check valve above the

ground.

Figure 1

ELECTRICAL INFORMATION

1. Employ a licensed electrician to perform the wiring. All wiring

must be done in accordance with applicable national and

local electrical codes.

2. Check that the power supply corresponds with the electrical

rating of the submersible motor and the control box (if

required). Make sure that the control box electrical rating

matches the motor electrical rating.

3. Every installation requires a fused disconnect switch or

circuit breaker.

4. Every installation must be grounded. There must be a reliable

ground connection between the pump and the distribution

panel. The motor lead incorporates a green grounding

conductor.

5. Lightning arrestors are recommended for every installation.

All stainless steel, single phase motors through 5HP

have built-in lightning arrestors. 3-phase motors require

a separate lightning arrestor installed as close to the

installation as possible. Install the arrestor in accordance

with manufacturer’s recommendations. Lightning arrestors

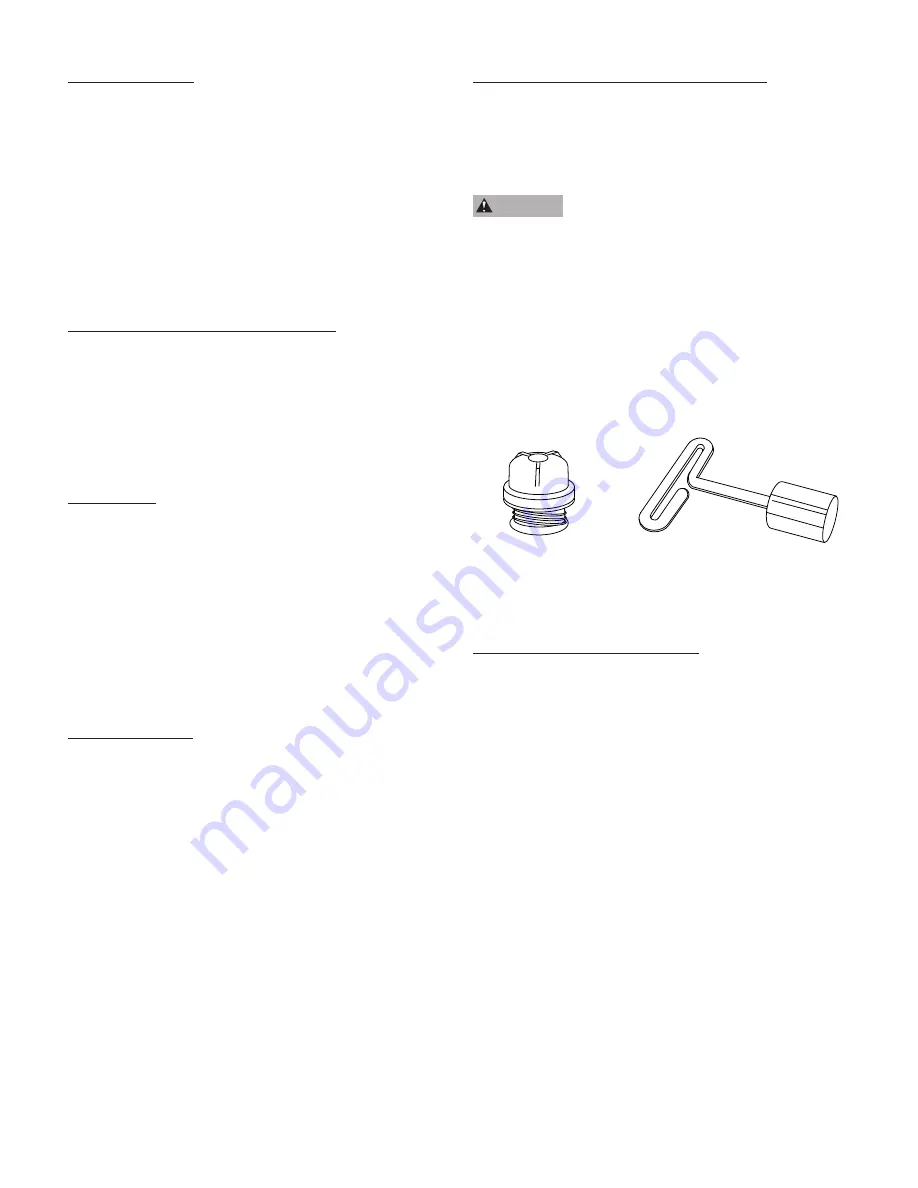

Poppet Assembly

T-Handle Poppet Wrench

REMOVABLE POPPET CHECK VALVE

4” submersible pumps with a 1-1/4” discharge are supplied

with a spring-loaded, removable poppet check valve assembly

(Figure 1). This check valve can be removed from the pump

discharge when drain back is desired.

W A R N I N G

Fluid draining back through the pump can

cause the pump to rotate backwards. If pump/motor starts

during this time, damage to the pump can occur.

The check valve can be removed using a T-handle poppet

wrench (purchased separately), or with standard needle-

nosed pliers. The poppet assembly is left-hand threaded and

is removed by turning clockwise. When reinstalling a poppet

check valve assembly, tighten it to 15 inch-pounds.