Clean Coils and Inspect Drawer Gaskets

Quarterly

RF 19 Q01

Document Part #19011151 – Rev. C – Revised 5/23/2018

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2007

Page 1 of 2

Frank

e

Fo

ods

er

vic

e S

olu

tions

C

onv

er

tibl

e Co

ole

r F

reez

er

Qu

art

erl

y

RF

19 Q

01

Why

The condenser coil requires regular cleaning to maximize the unit’s performance. Failure to do so

could lead to premature refrigeration system failure, additional energy usage, quality and safety

risks for food product and voiding of warranty.

Time required

5 minutes to prepare

10 minutes to complete

Time of day

Evening after closing

For 24-hour restaurants: during low volume period

Hazard icons

Tools and supplies

Soft Bristled

Brush

Heat-resistant

gloves

Procedure

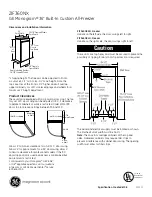

1

Turn unit off

Flip the rocker switch to the

OFF position to power down

the refrigerated drawers.

Unplug the equipment from

the electrical outlet.

Potential shock hazard.

2

Remove louvered panel

Panel is located on the lower

left side of the equipment.

Lift up on the panel and pull

away from the side of the

equipment to remove.

Louvers may have sharp

edges.

3

Clean condenser coil

Using a soft-bristled brush,

remove all dirt, dust, and

debris from the coil.

Surfaces inside of the

condenser compartment may

be hot. Wear heat-resistant

gloves when accessing

condenser coil.

Always brush in the direction

of the coil fins.

4

Reinstall louvered panel

Insert the six (6) tabs of the

louvered panel into the slots

around the condenser coil

opening, and then lower the

panel to lock it into place.

Louvers may have sharp

edges.