Oil flow rate to low

If the oil flow rate is too low insufficient heat will be

produced to vaporise the oil entering the burner, this will

result in the fuel being burnt as liquid which will wick from

the bottom of the burner creating smoke. The same

symptom can occur with excessive chimney draught at low

fire as the amount of air passing through the burner will cool

the burner preventing vaporisation of the fuel.

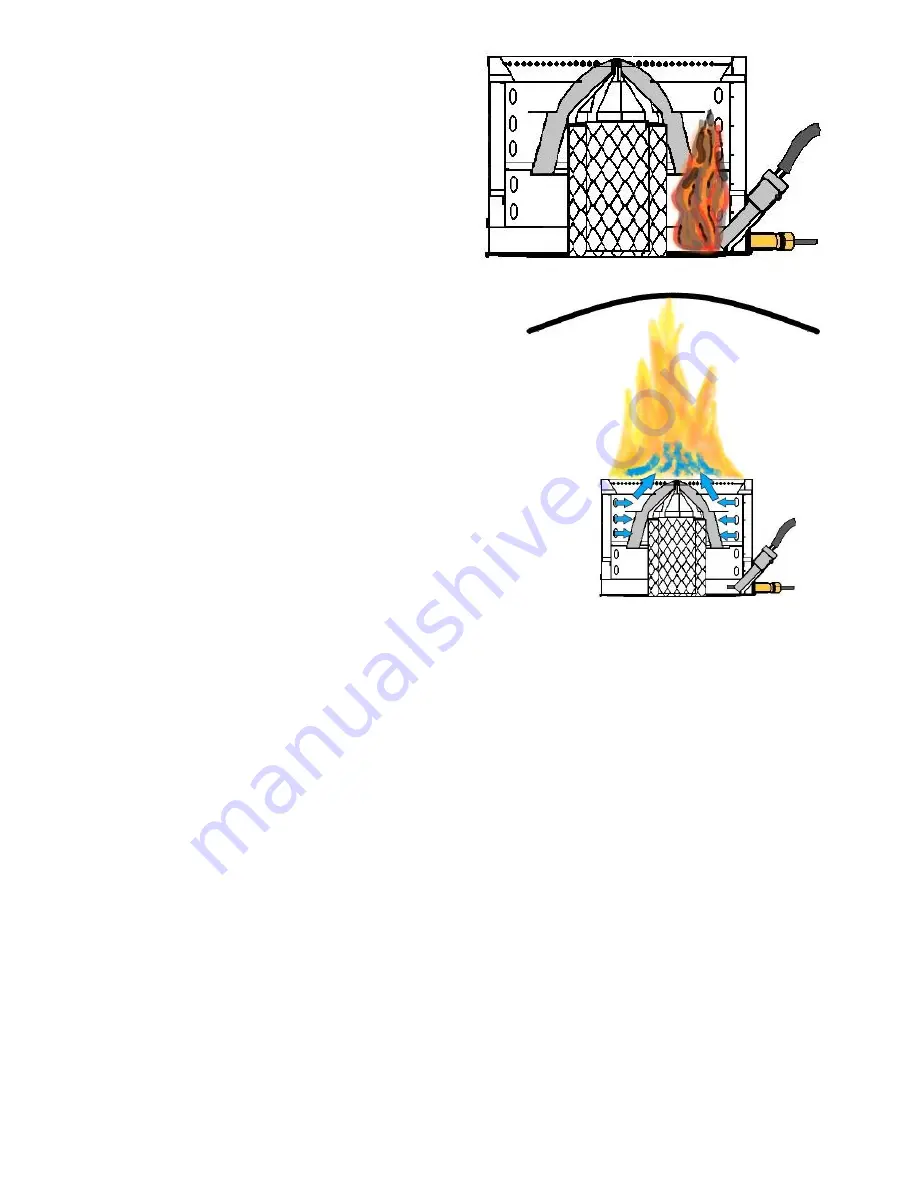

Maximum flame size (no 6 setting)

The maximum flame size, depending on the chimney draught

requirements, should not touch the top of the stove. The size of the

flame depends on the chimney draught produced.

If insufficient draught is created a tall long lazy yellow and

sometimes sooty flame will occur.

If excessive the flame size will be small and noisy within the burner.

A good guide is that the flame should not pass higher than the top

of the glass in the door. If a poor flue draught occurs the flame at

maximum flow rate should be adjusted to reduce the flow rate to

gain a correct maximum flame.

Solving Negative Pressure Problems

What to do if the chimney draught is too high at low fire.

There are two reasons chimney draught can be high at low fire.

1. The chimney is susceptible to increases of draught from external conditions such as wind.

If this is the case the flue termination position must be examined to confirm it is correct and a draught stabilising cowl

fitted.

2. Excessive negative pressure can occur with chimneys over 20ft (6 meters).

Utilize the draught stabiliser at low setting to reduce the chimney draught. This solution can only be used if the higher

heat settings of the stove are unlikely to be required.

In this case adjust the draught stabilizer to reduce the flue draught at setting 1 to 0.045” water gauge. Turn the control

knob to setting 6 maximum and reduce the high fire oil flow setting to decrease the flame size until a clean soot free

flame is produced.

A 90mm choke plate, FB237405, can be fitted under the flue collar which will reduce flue draught where there is a

high flue draught due to the chimney being tall. It cannot be used where the high flue draught is due to wind induced

conditions.

What to do if the chimney draught is too low at high fire setting.

This problem will only normally occur with poor flue construction or an unlined flue or short chimneys. The only

solution to this is to improve the chimney system or calibrate the high fire oil flow to reduce the flame size so it burns

cleanly.

As many stoves will never be run at high fire the reduction in the flame size on high is generally not a problem in

comparison to soot formation within the stove.