Mixer Gap Adjustment

Maintaining the proper clearance between the bottom tips of the mixer and the floor of the sample

cell is critical to prevent premature mixing motor failure.

If the gap is too high the mixing balls become jammed under the tips of the mixer, and/or come out

of the top of the cell through the sample water exit gap. If the mixer is set too low it will rub against

the floor of the sample cell. Either situation can damage the mixing motor. Intermittent mixer motor

stopping or reversal can be a symptom of these problems.

These same symptoms can also be caused by a worn copper ring, where the wall thickness has

diminished such that the mixing balls get jammed between the side of the mixer and the inside wall

of the copper ring. This latter condition would require replacement of the copper ring, in addition to

the gap adjustment described here.

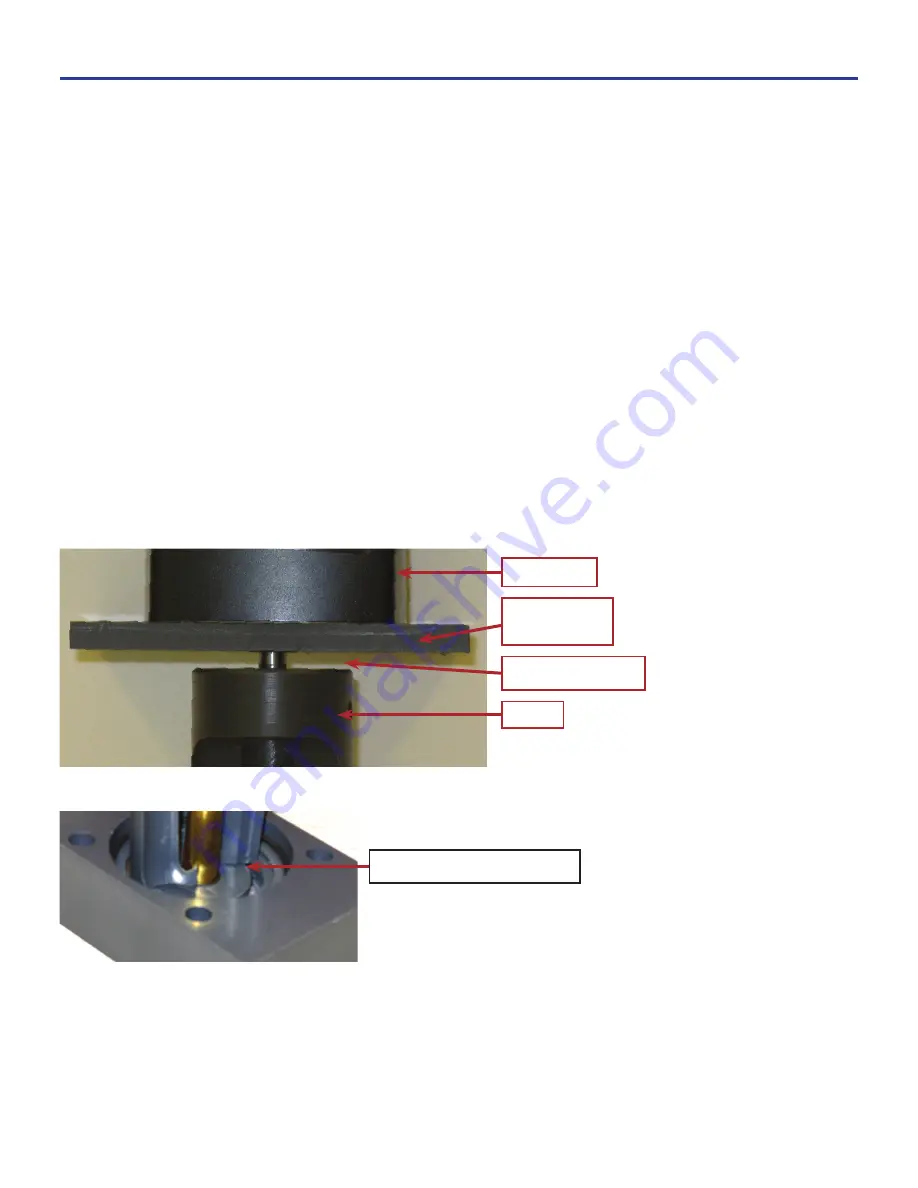

The mixer clearance gap must be checked and adjusted to 5/32” whenever any integral part of the

sample cell has been replaced, such as the mixer motor, the copper ring, or the O-rings.

Tech Tip:

Use a 5/32” drill bit to set the gap between the mixer and mounting plate.

Proper Spacing 5/32”

Mixing Motor

Mixing Motor

Mounting Plate

Mixer

Lifted enough to prevent rubbing

Figure 48

Figure 49

Maintenance

40

FX-1000p