CHAPTER 1

1.1 Introduction

OMC-W36 is a user programmable heat oven with a vertical tray used for

hardening the epoxies used during the assembly of fiber optic connectors. It is

primary intended to heat the fiber optic ferrules and plug type fiber optic connectors

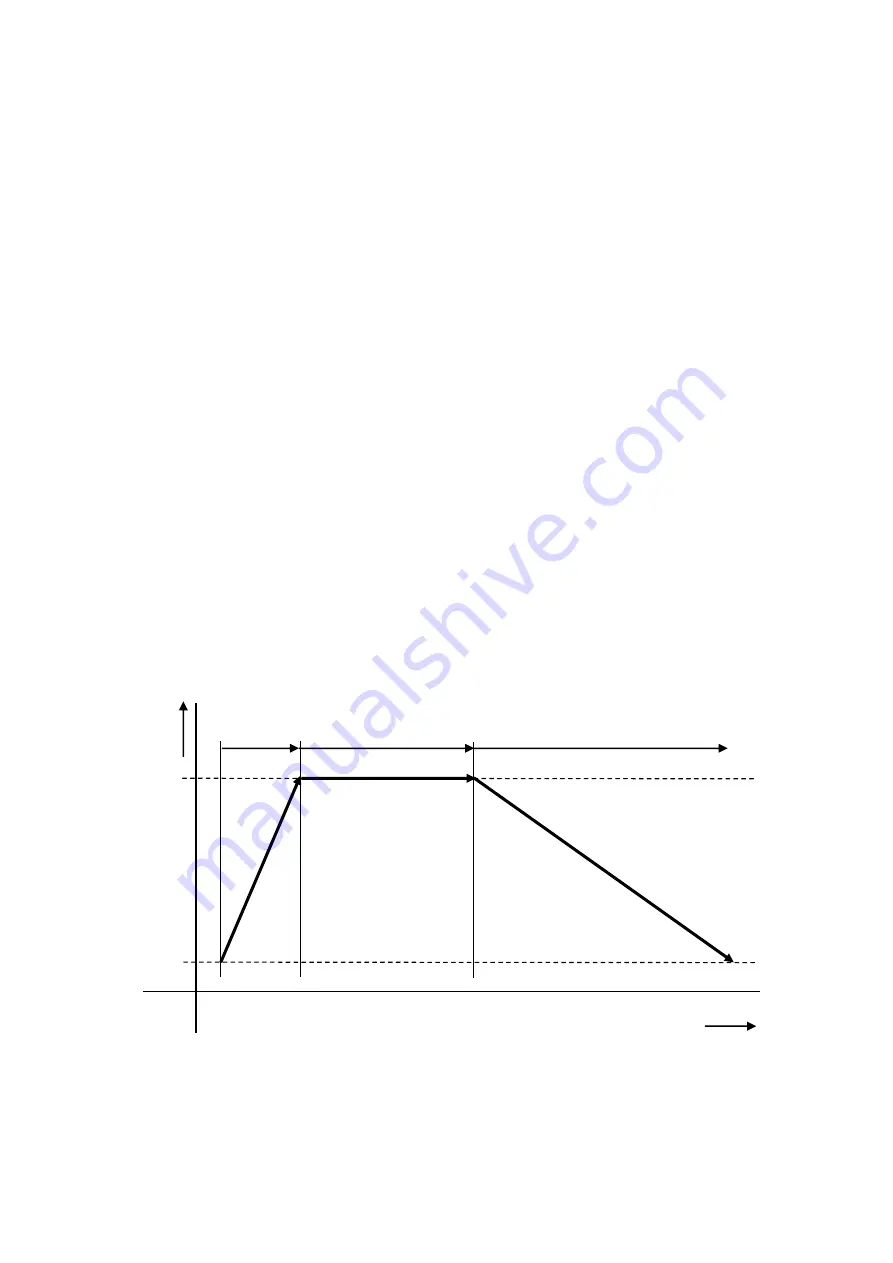

in which the epoxies bond the optical fiber. Heating process usually consists of three

(3) subsequent periods (steps):

-

warm up period: during this period the heat oven heats the cassette

with loaded fiber optic parts (ferrules, plugs). This time period cannot

be set by customer and is determined by internal components and

ambient temperature. This period can be interrupted manually by the

operator at anytime

-

cure period: during this period the temperature of the cassette remains

stable at certain temperature level for desired time. The temperature

and time depends on epoxies manufacturer recommendations.

Operator can set cure temperature and cure time manually. This period

can be interrupted manually by the operator at anytime

-

cool down period: as soon as the cure time is over, the cassette starts

to cool. Cooling is caused only by the influence of an ambient

environment. The unit remains in this condition unless the operator

starts the heating process again.

Figure 1.1.1. The heating process explanation

Ambient

temperature

Preset cure

temperature

warm up

period

cure period = preset

cure time

cool down

period

Te

m

pe

rt

ure

sc

ale

(°C

)

Time scale

(min.)

Summary of Contents for OMC-W36

Page 2: ...Blank page ...

Page 6: ...Blank page ...