Table of contents

3QLCLM

Edition: 04/2014

27

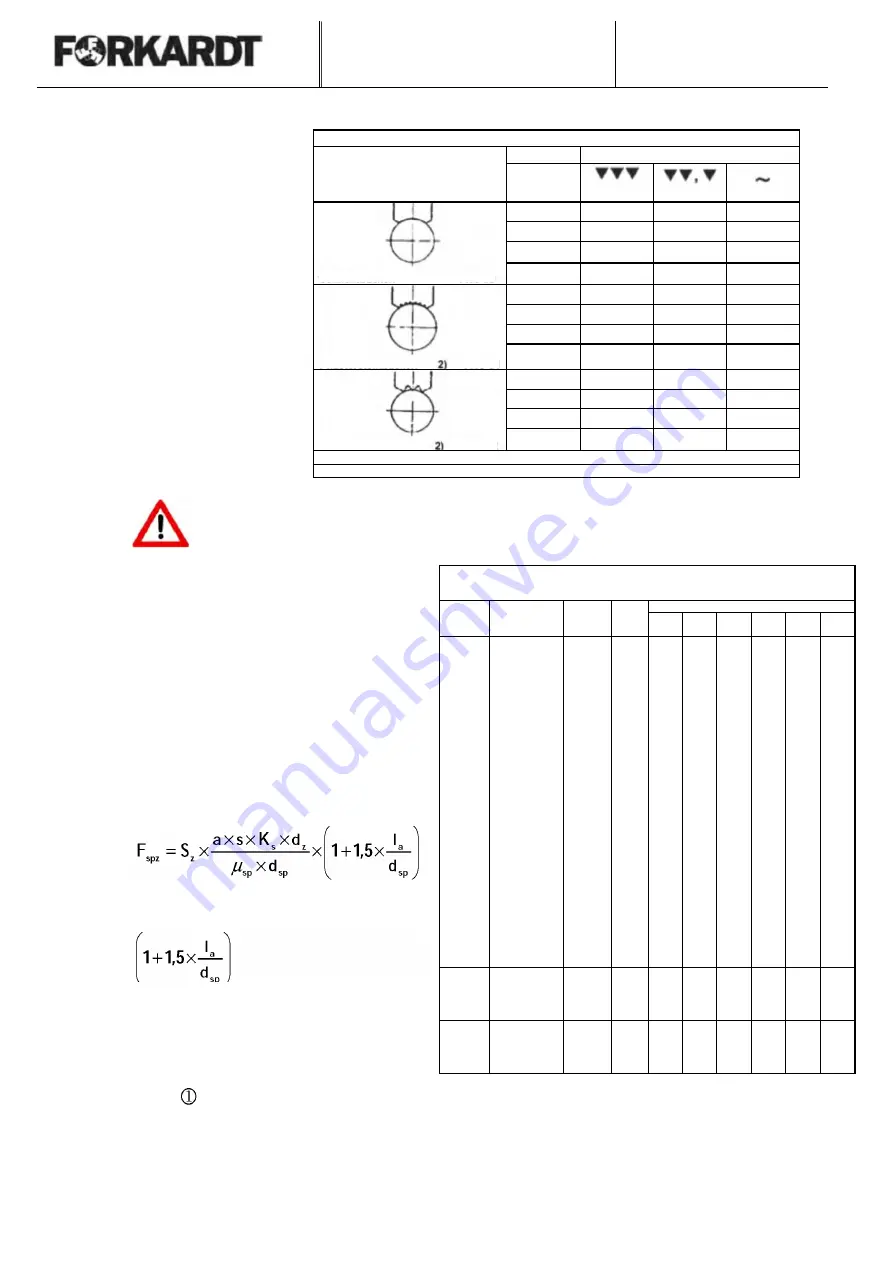

Terms used in the formulas:

Gripping coefficient μsp

Jaw design

Material

Material surface at the gripping point

l

a

=

Overhang of the work

piece

a

=

Depth of cut

Steel

0.1

0.15

- 1 )

s

=

Feed

AI

0.1

0.14

-

K

s

=

Specific cutting force

Ms

0.09

0.14

-

GG

0.08

0.12

-

d

z

=

Machining diameter

Steel

0.12

0.20

0.32

d

sp

=

Gripping diameter

AI

0.11

0.19

0.30

μ

sp

=

Gripping coefficient

Ms

0.11

0.18

0.27

F

s

=

Primary cutting force

GG

0.10

0.16

0.26

Steel

0.25

0.35

0.50

AI

0.24

0.33

0.48

Ms

0.23

0.32

0.45

GG

0.20

0.28

0.40

1) Avoid, smooth jaws are only suitable for gripping machined surfaces

2) Indentations will be produced on the work piece.

The cutting forces increase as the cutting tool becomes dull. An additional factor of safety

S

z

=2

is recommended to allow for all uncertainties in the machining process.

The gripping force must be increased to

allow for the tilting effect caused by the

overhang

.

Specific cutting force Ks (N/mm

2

) for feed s and

Adjustment angle 70°

(Source König, Essel )

Material no.

Material

Tensile

strength

B

N / mm

2

at

m/min

Feed s (mm)

0.16

0.25

0.40

0.63

1.00

1.60

1.0401

C15G

373

100

2482

2169

1916

1687

1481

1298

The tilting force need not be taken into

account if the work piece is supported by a

tailstock or if the work piece does not

project beyond the jaws by more than 0.5 x

d

sp

. The gripping force F

spz

required can be

found approximately from the formula:

1.0501

C35G

490

100

2577

2237

1927

1668

1441

1241

1.0532

St50-2

559

100

2561

2248

1959

1716

1499

1307

1.0632

St70-2

624

100

2877

2492

2142

1851

1595

1371

1.0711

9S20

371

100

1609

1553

1497

1444

1393

1342

1.1181

Ck35V

622

100

2574

2266

1962

1741

1527

1339

1.1191

Ck45V

765

100

2524

2253

1999

1781

1584

1405

1.1221

Ck60V

673

100

2548

2296

2058

1851

1662

1490

1.3505

100Cr6G

624

100

2904

2551

2239

1968

1726

1510

1.4113

X6CrMo17G

505

100

2378

2107

1854

1638

1445

1272

1.4305

X12CrNiS18.8

638

350

2596

2192

1835

1545

1296

1065

1.5752

14NiCr14BF

658

100

2249

2012

1790

1598

1424

1266

1.5919

15CrNi6

510

100

2271

2051

1842

1661

1494

1342

1.5920

18CrNi8G

578

100

2360

2095

1847

1636

1446

1276

. Tilting factor:

17131

16MnCr5G

510

100

2641

2244

1891

1603

1354

1141

1.7147

20MnCr5G

568

100

2452

2174

1915

1694

1495

1317

1.7225

42CrMo4V

1138

100

2428

2249

2075

1919

1773

1635

1.8515

31CrMo12V

1060

100

2678

2419

2173

1960

1764

1565

1.8519

31CrMoV9V

931

100

2507

2265

2036

1836

1653

1485

3.1354

AlCuMg2

15Hv10

200

953

649

752

66»

593

525

This equation cannot be applied to stepped

work pieces whose gripping diameter is

appreciably smaller than the machining

diameter.

-

G-AlMg4SiMn

260

200

829

729

636

558

-

-

3.3561.01

G-AlMgS

75HV10

200

886

797

713

641

574

514

0.4020

GG-20

178HB

200

1637

1444

1227

1047

892

757

0.6030

GG-30

206HB

100

1919

1595

1313

108»

899

740

0.7050

GGG 50

194HB

200

1840

1606

1392

1213

1053

913

The feed thrust component F

v

and passive thrust F

p

are not entered in this

formula. They are taken into account with safety factor S

z

!

Simple jaw

FNC 50

FNC 51

Stone jaw

Roughing jaw

FNC 52