M-6007-Z460FFT(FRT)

Crate Engine

GUIDE

NO PART OF THIS DOCUMENT MAY BE REPRODUCED WITHOUT PRIOR AGREEMENT AND WRITTEN PERMISSION OF

FORD PERFORMANCE PARTS.

Techline 1-800-367-3788

Page 14 of 24

IS-1850-0636

Factory Ford shop manuals are available from Helm Publications, 1-800-782-4356

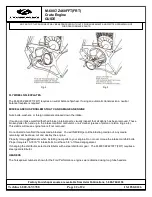

ENGINE INSTALLATION AND TUNING TIPS:

Performance engine durability is dependent on several supporting systems including:

Oiling system

o

Priming

o

Oil pan

o

Oil type

o

Capacity

o

Valve covers

Ignition system

o

Distributor gear installation

o

Distributor installation

Fuel delivery system

Cooling system

Flywheel, torque converter and transmission

o

Bellhousing alignment

If the support systems are not adequate, poor engine performance and possible engine failure could result.

OILING SYSTEM-CONSIDERATIONS/COMMON PROBLEMS

The M-6007-Z460FFT(FRT) engine is equipped with a high performance oil pan

. M-6007-Z460FFT has a TOTAL

OIL CAPACITY OF 9 QUARTS. The M-6007-Z460FRT has a TOTAL CAPACITY OF 7 QUARTS

. Priming the

oiling system before starting a new engine is crucial to engine life. This is important on initial start-up of a new

engine or, if the engine has not been run for an extended period of time.

PRIMING

Initial priming is done before installing the engine into the vehicle. Additionally, prime the engine prior to installing

the transmission. If there are any oiling system problems, it is easier to fix them with the engine out of the car. The

engine should be primed once more after installation before starting the engine. This is very important if hooking up

a remote filter and/or oil cooler.

DO NOT PRIME BY CRANKING ENGINE! Check oil level after priming engine and before starting.

STEP 1:

Use 5/16” priming tool or ¼" drive, 5/16” deep-well socket with extension for M-6007-Z

460FFT(FRT).

STEP 2:

Install mechanical oil pressure gauge.

STEP 3:

Remove valve covers.

STEP 4:

Rotate priming tool counterclockwise using an electric drill.

STEP 5:

Observe oil pressure achieved on gauge.

STEP 6:

Prime until oil comes up through the rocker arms. This may require rotation of the crankshaft to

obtain oil flow through all the rocker arms.

STEP 7:

Look for external oil leaks.

STEP 8:

Reinstall valve covers.