11

FMTD64

8.

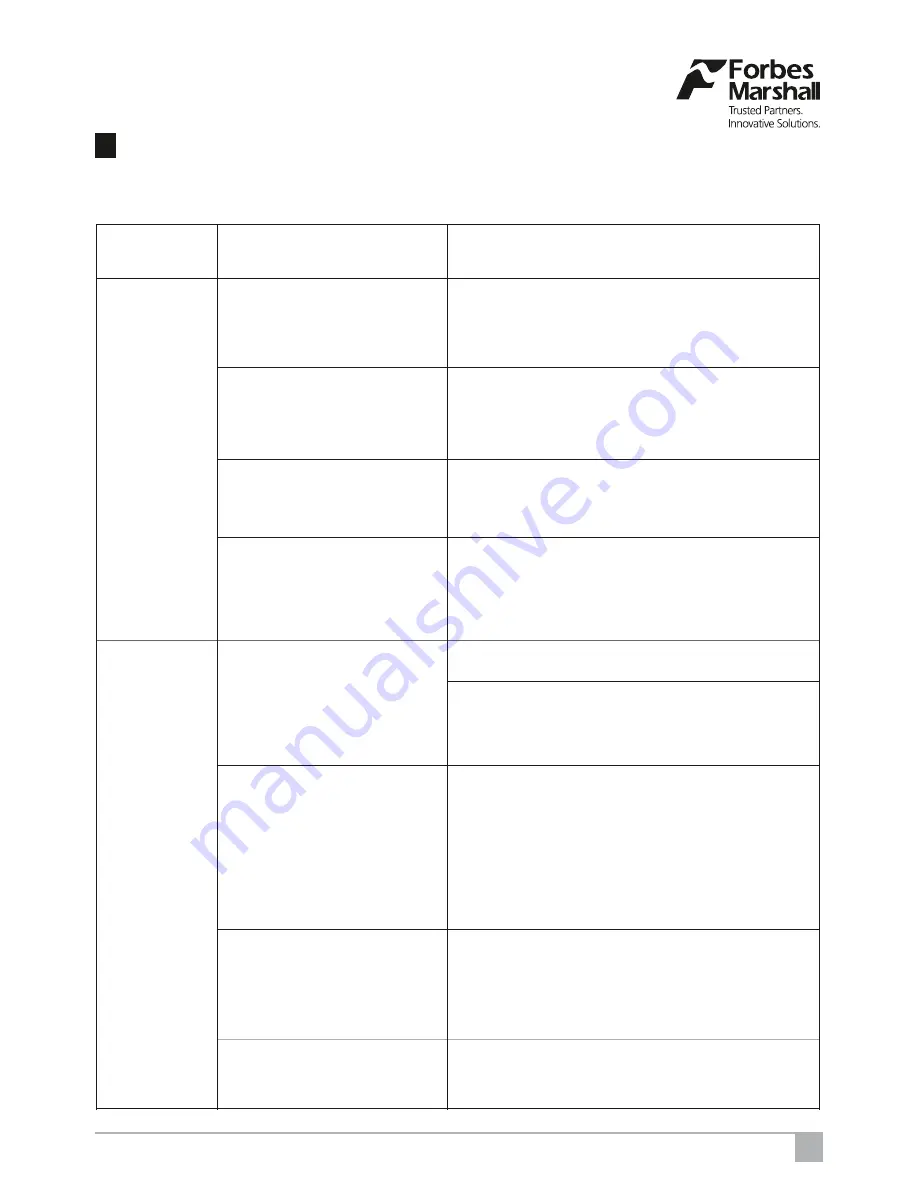

Troubleshooting:

If the expected performance is unachievable after installation of the Forbes Marshall

thermodynamic trap, check the following points for appropriate corrective measures.

Failure Mode Possible Cause

Remedy

No

condensate is

discharged

(blocked).

Inlet drip leg or strainer

screen is clogged with rust or

scale.

Flush inline drip leg and clean strainer screen. If

strainer screen is rusted, replace with new

strainer screen.

Differential pressure is low.

Verify inlet and outlet pressure of the steam trap.

Minimum differential pressure required is 0.25

bar g

Air – Binding problem.

Loosen cap and tighten to suitable torque.

Steam trap body is hot but no

condensate discharge.

To release flash steam locked (trapped) inside the

steam trap, pour water on cap of the steam trap

to check it discharge condensate.

Steam

leakage.

Steam Leaking continuously.

Ensure bypass valve is fully closed.

Check installation i.e. cap to be on top and fluid

flow direction same as arrow on the steam trap

body

Foreign material or oil film on

disc or body seat.

Clean both disc and body seat, flatness on disc

and body seating faces can be improved by

lapping individually on flat surface or glass plate.

Note:

The total amount of metal from body seat

face removed should not exceed 0.25mm

(0.01”).

Disc stuck to the cap.

Give a light tap on top of the cap and check if

step (inner surface of the cap) is worn out. If step

is worn out replace with new steam trap.

Back pressure exceeds

allowable value.

Outlet pressure of the steam trap should not

exceed 80% of the inlet pressure.