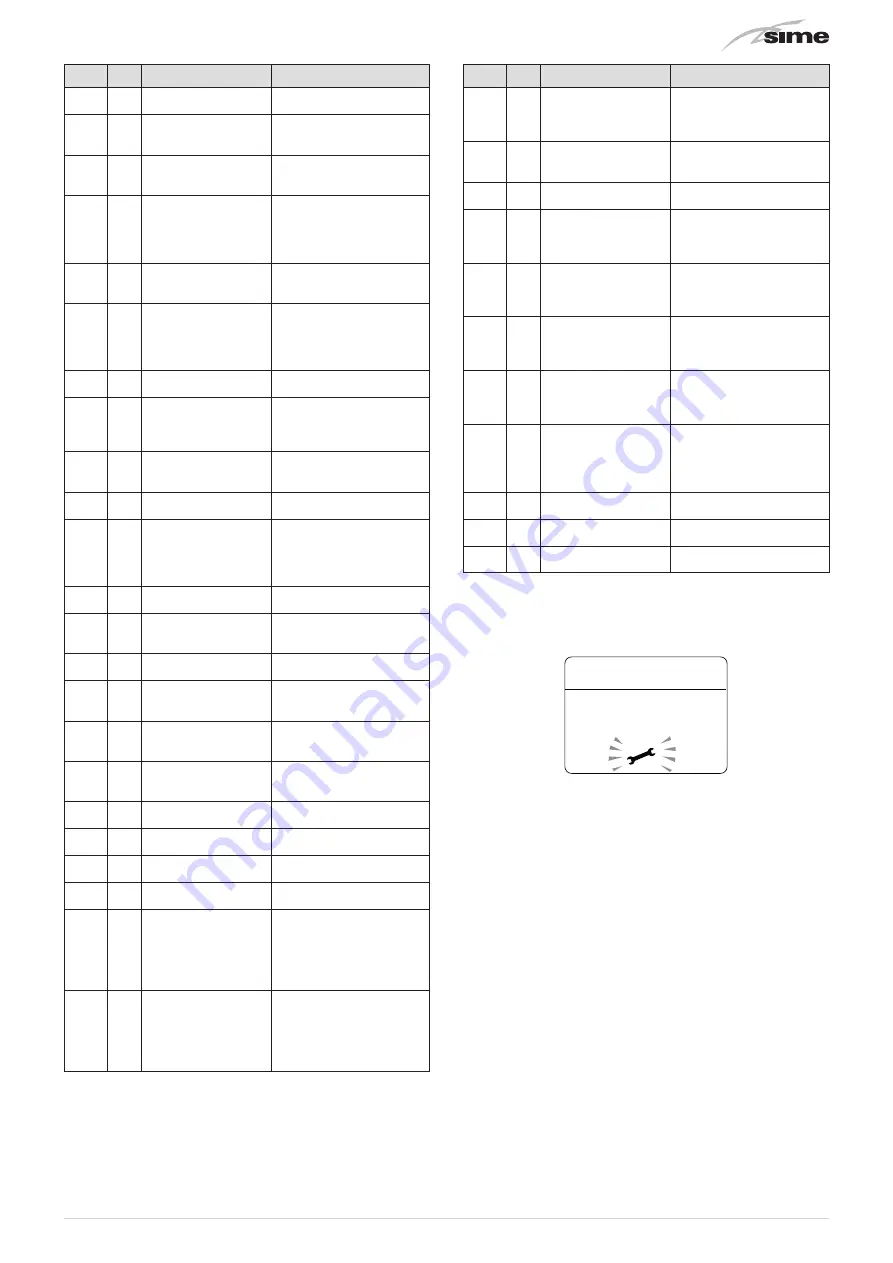

47

Type

No. Fault

Solution

ALL

11 Gas valve modulator

disconnected

- Check the electrical con-

nection

ALL

12

Incorrect configuration

of the open /sealed

chamber

- Set the parameter tS 0.4

(Combustion configuration)

to 0

ALL

13 Smoke probe inter-

vention

- Check the sensor is

working

- Replace the smoke probe

ALL

14 Smoke probe fault

- Replace the smoke probe

- Check the electrical con-

nection of the smoke probe

- Contact the Technical

Assistance Centre

ALL

15 Fan check cable dis-

connected

- Check the connection cable

between the fan and the

board

ALL

18 Condensate level fault

- Check for any clogging in

the pipe which takes the

condensate to the siphon

- Check that the siphon is

not clogged

ALL

28 Maximum number of

consecutive releases

- Contact the Technical

Assistance Centre

ALL

30 Return sensor (SR)

fault

- Replace the return probe

- Check parameters

- Contact the Technical

Assistance Centre

ALL

37 Fault due to low net-

work voltage

- Check the voltage

- Contact your network

provider

ALL

40 Incorrect network

frequency detected

- Contact your network

provider

ALL

41 Flame loss more than 6

consecutive times

- Check the detection

electrode

- Check the gas supply (open

valve)

- Check mains gas pressure

ALL

42 Button fault

- Check that buttons are

working

ALL

43 Open Therm communi-

cation fault

- Check the electrical

connection of the remote

control

ALL

44 No flame valve opening

time sum anomaly

- Replace the board

ALL

62 Self-calibrating proce-

dure is required

- Carry out the self-cali-

brating procedure (see the

specific section)

ALL

70 HP high pressure time

max. interventions

- Decrease setting PAR 46

- Contact the Technical

Assistance Centre

ALL

72 Incorrect positioning of

the delivery sensor

- Check that the delivery

sensor is attached to the

delivery pipe

ALL

77 EV current max/min

absolute limits error

- Check gas valve and board

ALL

78 EV current upper limit

error

- Check gas valve and board

ALL

79 EV current lower limit

error

- Check gas valve and board

ALL

80 Fault on the valve

control logic line

- Check/replace the connec-

tion cable to the gas valve

ALL

81 Block due combustion

during start-up

- Check for blockage in

chimney or recirculation

- Bleed the air from the gas

circuit

- Check for any dirt on the

air evaporator

ALL

82

Block due to numerous

combustion control

failures

- Check electrode

- Check outlets

- Check air diaphragm

- Check gas calibration

- Check for any dirt on the

air evaporator

Type

No. Fault

Solution

ALL

83 Irregular combustion

(temporary error)

- Check for blockage in

chimney

- Check for any dirt on the

air evaporator

ALL

84

Flow rate reduced for

(presumed) low pres-

sure on mains gas

- Check gas flow rate

ALL

88 Internal error (board

component protection) - Replace the board

ALL

89 Unstable combustion

feedback signal error

- Check electrode

- Check outlets

- Check air diaphragm

- Check gas calibration

ALL

90 Combustion set cannot

be reached error

- Check electrode

- Check outlets

- Check air diaphragm

- Check gas calibration

ALL

92

System has reached

maximum air cor-

rection error (at the

minimum flow rate)

- Check electrode

- Check outlets

- Check air diaphragm

- Check gas calibration

ALL

93 Combustion set cannot

be reached error

- Check electrode

- Check outlets

- Check air diaphragm

- Check gas calibration

ALL

95 Flame signal micro

interruptions error

- Check electrode

- Check board

- Check electric power

supply

- Check gas calibration

ALL

96 Block due to clogging

in smoke outlet

- Check for blockage in

chimney

ALL

98 SW error, board start-

up

- Contact the Technical

Assistance Centre

ALL

99 General board error

- Contact the Technical

Assistance Centre

8.7.1

Maintenance request

When it is time to perform maintenance on the boiler, the

c

symbol shows on the display.

Contact the technical assistance service to organise the neces-

sary work.