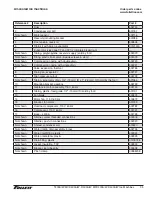

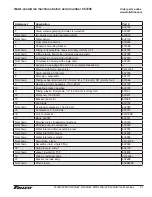

Service procedures

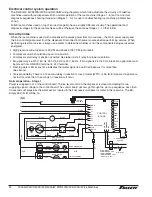

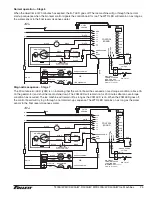

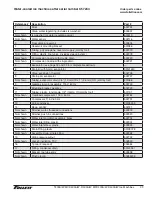

Evaporator disassembly (Fig. 7)

1. Disconnect power to ice machine.

2. Shut off water to ice machine.

3. Drain evaporator and float tank.

4. Disconnect plastic tubing from evaporator water inlet, drain pan

stub, compression nozzle tubing and reservoir overflow tubing from

secured clip.

5. Disconnect ice transport tube from compression nozzle.

Note: No compression nozzle on MFD400 series flake ice machines.

6. Loosen nut and remove upper vee band coupling from top of

evaporator.

7. Lift top bearing assembly straight up with a slight rotating motion and

remove.

8. Remove ice compression loop located at top of auger.

9. Lift auger straight up and out of evaporator.

10. Remove nut and lower vee band coupling from bottom of evaporator.

11. Lift evaporator to clear bottom bearing assembly.

12. Loosen hex head bolt in side of mounting base with 5/16 wrench and

lift lower bearing assembly.

13. Remove condensate shield.

14. Remove 4 Allen head machine screws holding mounting base to

gearbox.

15. If replacing evaporator, remove compression nozzle from evaporator

port.

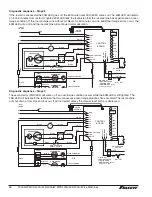

Evaporator reassembly (Fig. 7)

1. Clean gearmotor boss, output shaft and shaft well.

2. Install drain pan and evaporator mounting base.

3. Fill gearmotor shaft well with food-grade grease (Fig. 8).

4. Install condensate shield and seat against gearmotor boss.

5. Install mounting base O ring in groove in evaporator mounting base.

6. Lower bottom bearing assembly into evaporator mounting base.

7. While maintaining a downward pressure on bottom bearing assembly,

tighten hex head bolt with a 5/16 wrench.

8. Position evaporator over lower bearing assembly and align grooves

with pins in bearing assembly.

9. Install vee band clamp and nut and tighten to 70 in/lb.

10. Place auger in center of evaporator and rotate to mate with drive pin.

11. Install ice compression loop, orienting loop as shown in Fig. 7.

Note: No compression nozzle on MFD400 series flake ice machines.

12. Install upper bearing and seal assembly, rotating bearing to slip pin.

into auger slot.

13. Install upper vee band clamp and nut and tighten to 70 in/lb.

14. If evaporator was replaced, reinstall compression nozzle.

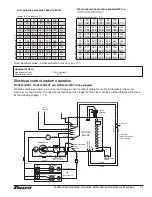

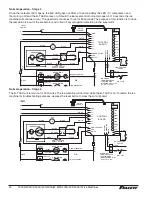

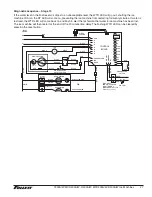

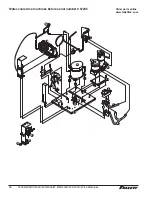

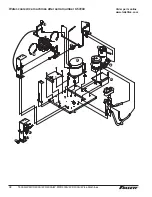

Gearmotor replacement (Fig. 8)

1. Disassemble evaporator as described above.

2. Disconnect the wire connectors.

3. Remove 4 screws holding gearmotor mounting plate to base of ice

machine and lift gearbox and motor clear of ice machine (Fig. 8.1).

4. Remove machine screws holding mounting plate to motor (Fig. 8.2).

5. Install new motor in reverse order.

1

2

apply

grease

here

Fig. 7

Fig. 8

T400A/W, MCD400A/W, R400A/W, MFD400A/W, D400A/W Ice Machines 29