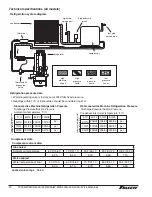

RIDE model ice machine ice transport tube installation

Incorrect ice transport tube installation can result in wet ice and dispensing problems. Follow guidelines below to

ensure correct installation. Call factory for assistance if you are unable to meet these requirements.

General requirements

§

Maximum length of tube run – 20 ft (6 m). Factory approval required for longer runs.

§

Run tube without dips.

§

One continuous length of tube; no splices.

§

Minimum radius of bends in tube – 6" (15.3 cm) inside radius.

§

Maximum number of bends – 6.

§

Insulation on entire run of ice tube.

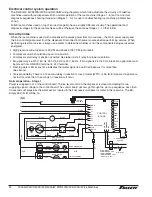

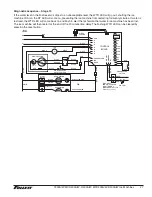

Procedure

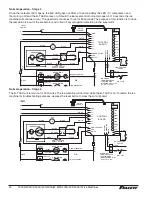

1. If installing MCD series ice machine refer to additional connection specifications for Vision series ice and

beverage dispensers instructions below.

2. Select side, rear or top knockout in ice machine cabinet for tube entrance.

3. Install supplied grommet in knockout.

4. Remove ice machine top panel.

5. Install supplied insulation on entire length of tube.

6. Run insulated tube without dips between ice machine and dispenser and secure in place.

7. Cut insulation off tube where tube enters grommet.

8. Slide end of tube without insulation through grommet and run to evaporator port.

9. Cut tube to that length.

10. Install a section of insulation on tube from grommet to evaporator port.

11. Slip supplied hose clamp over free end of tube.

12. Pull insulation back from free end of tube.

13. Push tube on evaporator port.

14. Position clamp behind lip on evaporator port and tighten clamp.

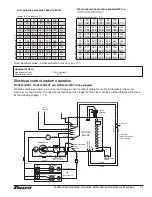

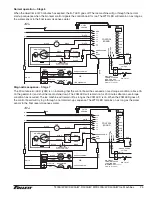

Correct installation

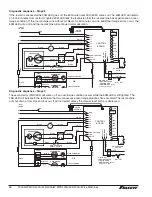

Incorrect installation

§

Length of run no more than 20 ft (6 m)

§

Tube run continuously from ice machine to

dispenser

§

Insulation on entire run of tube

§

No dips or tight bends

§

Tube secured in place

§

No splices

§

Dips in tube where water can collect

§

Splice or tight bend that restricts ice flow

§

Uninsulated tube that results in wet ice and

potential dispensing problems

T400A/W, MCD400A/W, R400A/W, MFD400A/W, D400A/W Ice Machines 15