SETUP AND OPERATION

| ENGLISH

19

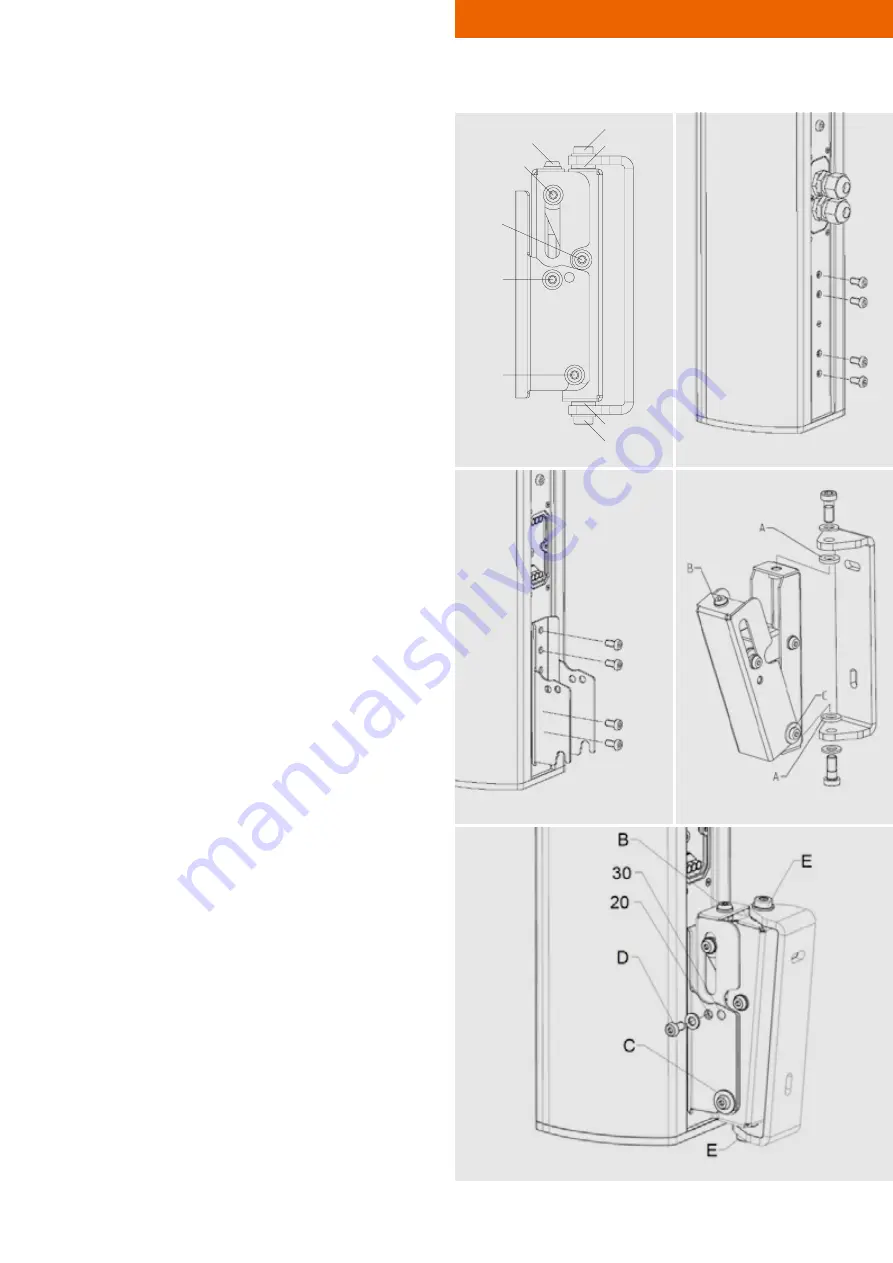

MOUNTING WITH WLX-100 / WLX-221 WALL BRACKETS

1. Remove both oval-head screws M6 (D) at the mount-

ing plate and loosen the screws (C, F, G) by about three

turns. Remove the mounting plate from the wall bracket.

SEE FIGURE 4.

2. Remove the four to six M6 oval-head screws that are lo-

cated underneath the connector panel.

SEE FIGURE 5.

3. Fix the loudspeaker to the

WLX-100/WLX-221

mount-

ing plate. Apply medium-strength thread lock fluid to

all screws. On both brackets, use four of the locking

screws you just removed. Tighten all screws according

to the required torque.

SEE FIGURE 6.

4. Fix the

WLX-100

or

WLX-221

to the building structure

using two screws and wall plugs. To do this, you will

need to disassemble the mounting bracket from the wall

bracket. During installation, don‘t forget to place the two

tooth-lock washers (A) between the mounting bracket

and the wall bracket. Make sure that the wall brack-

et is mounted with the horizontal slot facing upward.

SEE FIGURE 7.

5. Put the mounting bracket in a roughly vertical position by

turning the adjustment spindle (B) to the right.

6. Place the loudspeaker and its mounting plate on the

wall bracket. Both sides of the mounting plate must be

resting on the screw (C).

SEE FIGURE 8.

7. At this point the fixing screws (D) can be fitted and

tightened with a torque of 8-10 Nm. There are two op-

tions here: If the front holes (20) are to be used, this will

result in an adjustment angle of 0-20°; if the rear holes

(30) are used, this will result in an adjustment angle of

10-30°.

8. Set up the required inclination angle by turning the ad-

justment spindle (B) to the left. If you need to reduce

the angle again, turn the spindle back while pushing

the speaker slightly up towards the wall bracket and

thus releasing the spindle.

9. Loosen the clamping screws (E) on the horizontal axis

and turn the loudspeaker to its required position.

10. Once you are happy with the loudspeaker’s angle and

rotation, tighten the clamping screws (E) with a torque

of 20 Nm. Tighten the screws (C, F, G) with a torque of

8 to 10 Nm.

Figure 4

Figure 6

Figure 8

Figure 5

A

E

E

A

C

D

F

G

B

Figure 7