444 9160 / 444 9180 / 442 9020

33

E 219 GB - Issue 1

Initial operation

According to VGB 14 initial operation must be done by a specialist in the presence of the owner/user.

The specialist is obliged to instruct the owner/user in the use of the lift and to point out the dangers through

wrong operation, the safety indications according to the current law and the behaviour when faults occur.

It must be certified by the specialist in the enclosed test book.

Drive the vehicle in the middle between the two columns. Swivel the lifting arms under the vehicle and position

them under the points stipulated by the vehicle manufacturer.

Take care that the vehicle is evenly placed on all 4 carrying platforms.

In cases where our standard turntables are not suitable for the safe locating of a vehicle (i.e. offroad vehicle),

we recommend the wide range of accessories for special purposes.

Please observe the operational safety regulations.

Raising

The vehicle doors must be kept shut. Press the key “raise”( Heben) and observe the vehicle and the lift. When

the vehicle wheels have lost contact with the floor (after a height of approx. 30 cm), the lifting process must

be interrupted and the rubber turntables under the vehicle must be checked for safe positioning. Equally

important is a sight check of the lifting arm locks. The lifting process can be continued only after checking

that the automatic toothed segments of the lifting arm stopper are firmly anchored on each lifting arm/lifting

carriage. Check that nobody is present in the danger area. Press the “raise” key until the vehicle has been

hoisted to the required working height. When the lift has reached the upper end position, it stops

automatically. During the raising process neither persons nor objects must be present in the working area.

Avoid jerky raising actions.

Lowering

Check the danger area. During the lowering process neither persons nor objects must be present in the

working area of the lift or on the lifting platform.

Press the key “lower”, observe the vehicle and the lifting platform until the required height or the danger

area of approx. 120 mm above the lift base position has been reached.

At this height the lift stops automatically. If the key “lower” is pressed again, the lift can be driven back

into its base position.

During this lowering process in the danger area a warning signal tone is audible.

If one of the lifting carriages advances, so that the vehicle is out of phase, a brake on the advancing

motor will be operated by the alignment control system until the lifting carriage which is lagging behind

has reached the same level. During a working process the lift can undergo several alignments.

Jerking movement during lowering by pressing the lowering key must be avoided because this will

cause extreme oscillation of the lifting platform. When the lower end position has been reached, the lift

stops automatically and the lock of the lifting arm stopper is released automatically.

The lifting arms which are positioned under the vehicle loading points must be pushed together and

swivelled back into their base position. Drive the vehicle out of the lifting platform.

Note

The process described for the initial operation applies to each lifting and lowering process of the vehicle.

Caution: During operation, it may be noticed a burned grease odour. This is due to the high operating

temperature of the screw-nut set. This phenomenon is normal.

Summary of Contents for 442 9020

Page 13: ...444 9160 444 9180 442 9020 13 E 219 GB Issue 1 ...

Page 14: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 14 ...

Page 15: ...444 9160 444 9180 442 9020 15 E 219 GB Issue 1 ...

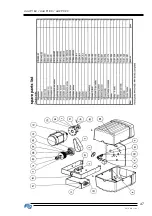

Page 17: ...444 9160 444 9180 442 9020 17 E 219 GB Issue 1 Lifting arms for type 442 9020 ...

Page 21: ...444 9160 444 9180 442 9020 21 E 219 GB Issue 1 ...

Page 23: ...444 9160 444 9180 442 9020 23 E 219 GB Issue 1 ...

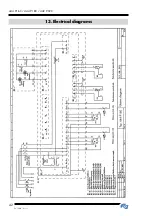

Page 42: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 42 13 Electrical diagrams ...

Page 43: ...444 9160 444 9180 442 9020 43 E 219 GB Issue 1 ...

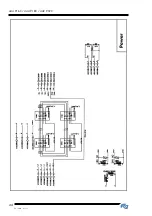

Page 44: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 44 ...

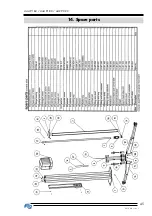

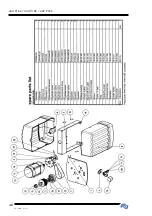

Page 45: ...444 9160 444 9180 442 9020 45 E 219 GB Issue 1 14 Spare parts ...

Page 46: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 46 ...

Page 47: ...444 9160 444 9180 442 9020 47 E 219 GB Issue 1 ...

Page 48: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 48 ...

Page 49: ...444 9160 444 9180 442 9020 49 E 219 GB Issue 1 ...

Page 50: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 50 ...

Page 51: ...444 9160 444 9180 442 9020 51 E 219 GB Issue 1 ...

Page 52: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 52 ...

Page 53: ...444 9160 444 9180 442 9020 53 E 219 GB Issue 1 ...

Page 54: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 54 ...

Page 55: ...444 9160 444 9180 442 9020 55 E 219 GB Issue 1 ...

Page 56: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 56 ...

Page 57: ...444 9160 444 9180 442 9020 57 E 219 GB Issue 1 ...

Page 58: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 58 ...

Page 59: ...444 9160 444 9180 442 9020 59 E 219 GB Issue 1 ...

Page 60: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 60 ...

Page 70: ...444 9160 444 9180 442 9020 E 219 GB Issue 1 70 ...

Page 71: ...444 9160 444 9180 442 9020 71 E 219 GB Issue 1 ...