OPERATING INSTRUCTIONS

17

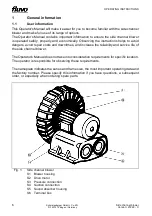

Side channel blower

Version: 27222 - C

Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

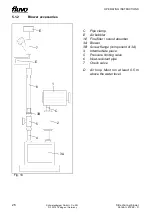

3.2

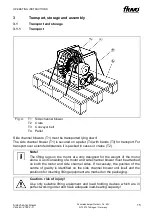

Unpacking, cleaning and assembly

3.2.1

Unpacking

The side channel blower is secured on a pallet with bands for transport. For transport over

extended distances it is packed in cases or crates.

After the retaining bands are loosened, lift the side channel blower out of the packaging

with auxiliary equipment (lifting tackle).

3.2.2

Cleaning

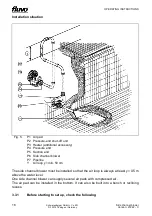

Various measures are provided for protection against transport damage or corrosion. Find

out which ones have been selected for your side channel blower.

1. Cover plates on the connections

2. Shaft protection, for delivery without motor

3. Protective paint on bare metal parts

Before set-up or installation of the side channel blower, these protective devices must be

removed. No contamination can be allowed to remain inside the side channel blower.

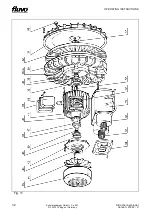

3.2.3

Assembly

The side channel blower generally comes premounted and is therefore ready for delivery.

3.3

Setting up and connecting

Note!

If possible do not use steam jet cleaners.

If you do, make certain not to damage the electric motor and bearings during

use.

Note!

Check to ensure the side channel blower is running easily and freely before

starting assembly

Other external accessories such as air chambers, etc., that are not

premounted on the side channel blower in the factory should not be connected

until after the side channel blower is installed in the system or on the foundation

of the side channel blower.

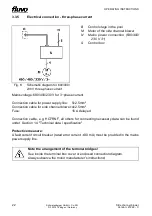

Explosion protection / safety instructions!

Electrical equipment that will be operated in areas subject to the risk of

explosion must meet explosion protection requirements. These are identified

by the factory plate on the motor. For installation in areas subject to the danger

of explosion, applicable local regulations for explosion protection and

requirements of the test certificate included with delivery, which was issued by

the office responsible for testing, must be observed. The test certificate

included with delivery must be kept in a safe place at the installation location

(for example in the supervisor's office, etc.).