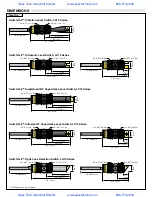

Step Nine

Step Ten

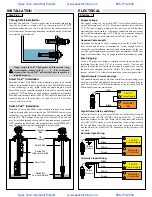

WIRING

WIRING

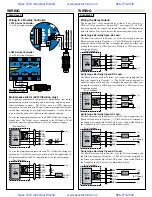

Models LU10-___5 Only:

The LU10-___5 level switch has been approved for use in Class I,

Groups A, B, C & D; UNDER CERTIFICATE NUMBER LR 79326-

4. DO NOT USE THE LZ12, LP15, LP10 or LO10 SERIES IN

INTRINSICALLY SAFE APPLICATIONS. The Entity parameter for

the LU10-___5 are:

Vmax = 32 VDC

Imax = 0.5 A

Ci = 0 µF

Li = 0 mH

Intrinsically Safe Control Drawing:

Wiring to a Flowline Controller:

LC90 Series Controller

4 or 20 mA Signal Output

Red Wire

Black Wire

Shield

HAZARDOUS LOCATION

Class I, Groups A, B, C & D

Class II, Groups E, F & G

Class III

NON-HAZARDOUS LOCATION

Sensor Drawing: LSD1

Rev. B 10-01-02

Sensor Models

LU10

Entity Parameters

V

max

= 32V

I

max

= 0.5A

C

i

⊕

0

L

i

⊕

0

Associated

Equipement

(see notes 1 and 4)

Notes:

1. CSA certified associated equipment with entity parameters.

2. V

max

≥

V

oc

,

I

max

≥

I

sc

,

C

i

+ C

cable

ʺ

C

a

., L

i

+ L

cable

ʺ

L

a

.

3. Installation should be in accordance with CEC Part I, or

NFPA 70.

4. Associated equipment must be installed per manufacturers

instructions

STANDARD

CONTROLLER

R E L A Y 1

R E L A Y 2

P O W E R

INPUT 1

INPUT 2A

INPUT 2B

- +

- +

INVERT

DELAY

INVERT

DELAY

LATCH

ON OFF

Black

Red

Non-Hazardous Area

Hazardous Area

Voc = 17.47 VDC

Isc = 0.4597 A

Ca = 0.494 µF

La = 0.119 µH

Vmax = 32 VDC

Imax = 0.5 A

Ci

= 0 µF

Li

= 0 µH

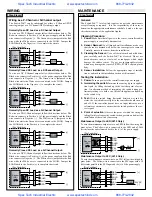

Models LU10-___5 Only:

The LU10-___5 level switch has been approved for use in Class I,

Division 1, Groups A, B, C & D; EEx ib IIC T6;

UNDER CERTIFICATE NUMBER LCIE 01.E6048X. DO NOT

USE THE LZ12, LP15, LP10 or LO10 SERIES IN INTRINSICALLY

SAFE APPLICATIONS. The Entity parameter for the LU10-___5

are:

North America

Europe

Vmax = 32 VDC

Ui = 32 VDC

Imax = 0.5 A

Ii = 0.5 A

Pmax = 1.3 W

Pi = 1.3 W

Ci = 0 µF

Ci = 0 µF

Li = 0 µH

Li = 0 µH

Intrinsically Safe Control Drawing:

Red Wire

Black Wire

Shield

HAZARDOUS LOCATION

Class I, Division1,

Groups A,B,C,D

EEx ib IIC T6

NON-HAZARDOUS LOCATION

Sensor Drawing: U10900

Sheet 1 of 2

Rev. B 4-02-01

Sensor Models

LU10-___5

Entity Parameters:

North America

V

max

= 32V

I

max

= 300 mA

P

max

= 1.3 W

C

i

= 0 µF

L

i

= 0 µH

Europe

U

i

= 32V

I

i

= 300 mA

P

i

= 1.3 W

C

i

= 0 µF

L

i

= 0 µH

Associated

Equipment

Entity Parameters:

North America

V

oc

≤ V

max

I

sc

≤ I

max

C

a

≥ C

i

+C

cable

L

a

≥ L

i

+L

cable

Europe

U

o

≤ U

i

I

o

≤ I

i

C

o

≥ C

i

+C

cable

L

o

≥ L

i

+L

cable

Red Wire

Black Wire

Shield

HAZARDOUS LOCATION

Class I, Division1,

Groups A,B,C,D

EEx ib IIC T6

NON-HAZARDOUS LOCATION

Sensor Drawing: U10900

Sheet 2 of 2

Rev. B 4-02-01

Sensor Models

LU10-___5

Entity Parameters for 12-32 Lines:

V

max

= 32V,

�

U

i

= 32V

I

max

= 300 mA,

�

I

i

= 300 mA

P

max

= 1.3 W,

�

P

i

= 1.3 W

C

i

= 0 µF,

�

C

i

= 0 µF

L

i

= 0 µH,

�

L

i

= 0 µH

Entity Parameters for Switch Outputs:

V

max

= 32V,

�

U

i

= 32V

I

max

= 500 mA,

�

I

i

= 500 mA

P

max

= 1.3 W,

�

P

i

= 1.3 W

C

i

= 0 µF,

�

C

i

= 0 µF

L

i

= 0 µH,

�

L

i

= 0 µH

Associated Equipment

Entity Parameters for 12-32 Lines:

V

oc

≤ V

max,

�

U

o

≤ U

i

I

sc

≤ I

max,

�

I

o

≤ I

i

C

a

≥ C

i

+C

cable,

�

C

o

≥ C

i

+C

cable

L

a

≥ L

i

+L

cable,

�

L

o

≥ L

i

+L

cable

Entity Parameters for Switch Outputs:

V

oc

≤ V

max,

�

U

o

≤ U

i

I

sc

≤ I

max,

�

I

o

≤ I

i

C

a

≥ C

i

+C

cable,

�

C

o

≥ C

i

+C

cable

L

a

≥ L

i

+L

cable,

�

L

o

≥ L

i

+L

cable

Green Wire

White Wire

Notes: PARAMETERS DEPEND ON OUTPUT TYPE

1.

�

Installation should be in accordance with CEC Part 1, or NFPA 70.

2.

�

Associated Equipment shall be CSA certified with entity parameters

�

connected in accordance with manufacturers instructions.

Spec Tech Industrial Electric www.spectechind.com

888-773-2832

Spec Tech Industrial Electric www.spectechind.com

888-773-2832