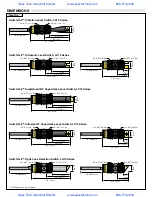

Step Seven

Step Eight

WIRING

WIRING

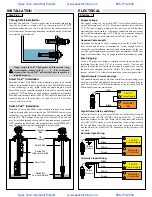

Wiring to a Flowline Controller:

LC10 Series Controller

(4 or 20 mA signal output)

LC40 Series Controller

(4 or 20 mA signal output)

INVER

T +/-

DELAY

AC

AC

GND

NC

C

NO

R

P

Input 1

(-)

115 VAC

220 VAC

(+)

Green - Not Used

Black

Shield - Not Used

White - Not Used

Red

STANDARD

CONTROLLER

R E L A Y 1

R E L A Y 2

P O W E R

INPUT 1

INPUT 2A

INPUT 2B

- +

- +

INVERT

DELAY

INVERT

DELAY

LATCH

ON OFF

Shld

Not Used - White *

Red

Black

Not Used - Green*

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

BLK

LOAD

LOAD

OR

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[Dry Condition]

Sensor

(NC)

BLK

GRN

SHLD

WHT

RED

LOAD

LOAD

OR

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

19 ±1 mA Dry

5 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[AC Power]

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

BLK

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

[AC Power]

[Dry Condition]

Sensor

(NC)

BLK

GRN

SHLD

WHT

RED

LOAD

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

19 ±1 mA Dry

5 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

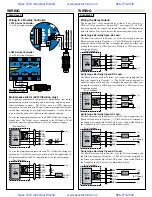

Wiring the Relay Output:

The Switch-Tek™ relay output can be wired as a dry contact to a

VDC or VAC power source. Switch-Tek™ does require 12 - 36 VDC

power to operate the sensor and switch the relay. All illustrations

below identify a Dry switch state as the normal position of the relay.

Switching a Normally Open DC Load:

The Red wire connects to Positive (+) of the power supply and the

Black wire connects to Negative (-). The LOAD can be attached to

either the Green or White wires. Complete the circuit by either con-

necting the Green to (+) VDC power or White to (-) VDC power (see

illustration below).

Switching a Normally Closed DC Load:

The Black wire connects to Positive (+) of the power supply and the

Red wire connects to Negative (-). The LOAD can be attached to

either the Green or White wires. Complete the circuit by either con-

necting the Green to (+) VDC power or White to (-) VDC power (see

illustration below).

Switching a Normally Open AC Load:

The Red wire connects to Positive (+) of the DC power supply and the

Black wire connects to Negative (-). The LOAD can be attached to

the Green wire and the Hot of the VAC power. Connect the White to

the Neutral of the VAC power (see illustration below).

Switching a Normally Closed AC Load:

The Black wire connects to Positive (+) of the DC power supply and

the Red wire connects to Negative (-). The LOAD can be attached to

the Green wire and the Hot of the VAC power. Connect the White to

the Neutral of the VAC power (see illustration below).

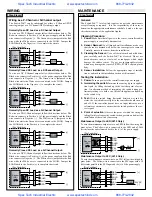

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

YEL

BLK

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5 ±1 mA Dry

19 ±1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

MAINT. ALARM

[YEL Wire]

NPN Transistor

10 mA Max.

2.2K

[Dry Condition]

Sensor

(NO)

RED

GRN

SHLD

WHT

YEL

BLK

PLC

[+]

[-]

SENSOR POWER

[RED & BLK Wires]

36 VDC Max.

5

±

1 mA Dry

19

±

1 mA Wet

RELAY RATING

[GRN & WHT Wires]

60 VA Max.

MAINT. ALARM

[YEL Wire]

NPN Transistor

10 mA Max.

10K

24 VDC

Maintenance Alarm (LZ12 Vibration only):

For optimum performance and proactive maintenance, the sensor

automatically adjusts for coating, and if necessary, outputs a preven-

tative maintenance alarm. The Yellow wire is a NPN transistor

designed to switch when a build-up of material prevents the vibration

switch from operating at its operational frequency. Use the Yellow

wire to identify when the Vibration switch requires cleaning.

To wire the maintenance output wire to an LED, follow the wiring dia-

gram below. The Yellow wire is connected to the LED and a 2.2kΩ

resister in series and referenced back to the (+) of the power supply.

To wire the maintenance output wire to an PLC, follow the wiring dia-

gram below. The Yellow wire is connected to the PLC input with a 10

kΩ resister parallel to the PLC input and the (+) of the power supply.

Spec Tech Industrial Electric www.spectechind.com

888-773-2832

Spec Tech Industrial Electric www.spectechind.com

888-773-2832