Installation and Maintenance Manual

Series 19 - Segmented Ball Valves

Date: Feb 2013 / Page 6 of 19

Installation and Maintenance Manual

Series 19 - Segmented Ball Valves

Date: Feb 2013 / Page 7 of 19

®

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2012 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2012 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

6. PREVENTATIVE MAINTENANCE

UÊ

At least once every six months, check for proper

operation by following the preventative maintenance

steps outlined below. These steps may be performed

while the valve is in line and without interrupting service.

If an internal problem is suspected, refer to section

“9”

for class 150/300 and “11” for class 600

.

UÊ

Look for signs of gasket leakage through the end flanges

and post. If necessary, re-torque end flanges and post

cover.

UÊ

Examine the valve for damage caused by corrosive

fumes or process drippings.

UÊ

Clean the valve and repaint areas of severe oxidation.

UÊ

Check the packing-box for proper tightness. If there is

a persistent leak, change the packing after referring to

sections

“9.3” class 150/300 and “11.2” class 600

for dismantling the valve, “9.5” class 150/300 and

“11.3” class 600 for Reassembling the valve.

CAUTION:

Do not over tighten packing. This can cause

excessive packing wear and high friction that may

impede stem movement.

UÊ

If the valve is equipped with a lubricator, add lubricant

if necessary.

UÊ

If possible, stroke the valve and check for smooth, full

stroke operation. Unsteady stem movement may indicate

an internal valve problem.

UÊ

Check the calibration of the positioner/controller if

available. For further preventative maintenance, see the

instructions in the installation, operation and maintenance

manual for the applicable positioner/controller.

UÊ

Ensure all accessories, brackets and bolting are securely

fastened.

UÊ

If possible, remove power source (air supply/electrical

signal) and observe actuator for correct fail-safe action.

UÊ

Check the actuator and all air connections for leaks.

UÊ

If an air filter is supplied, check and replace the cartridge

if necessary.

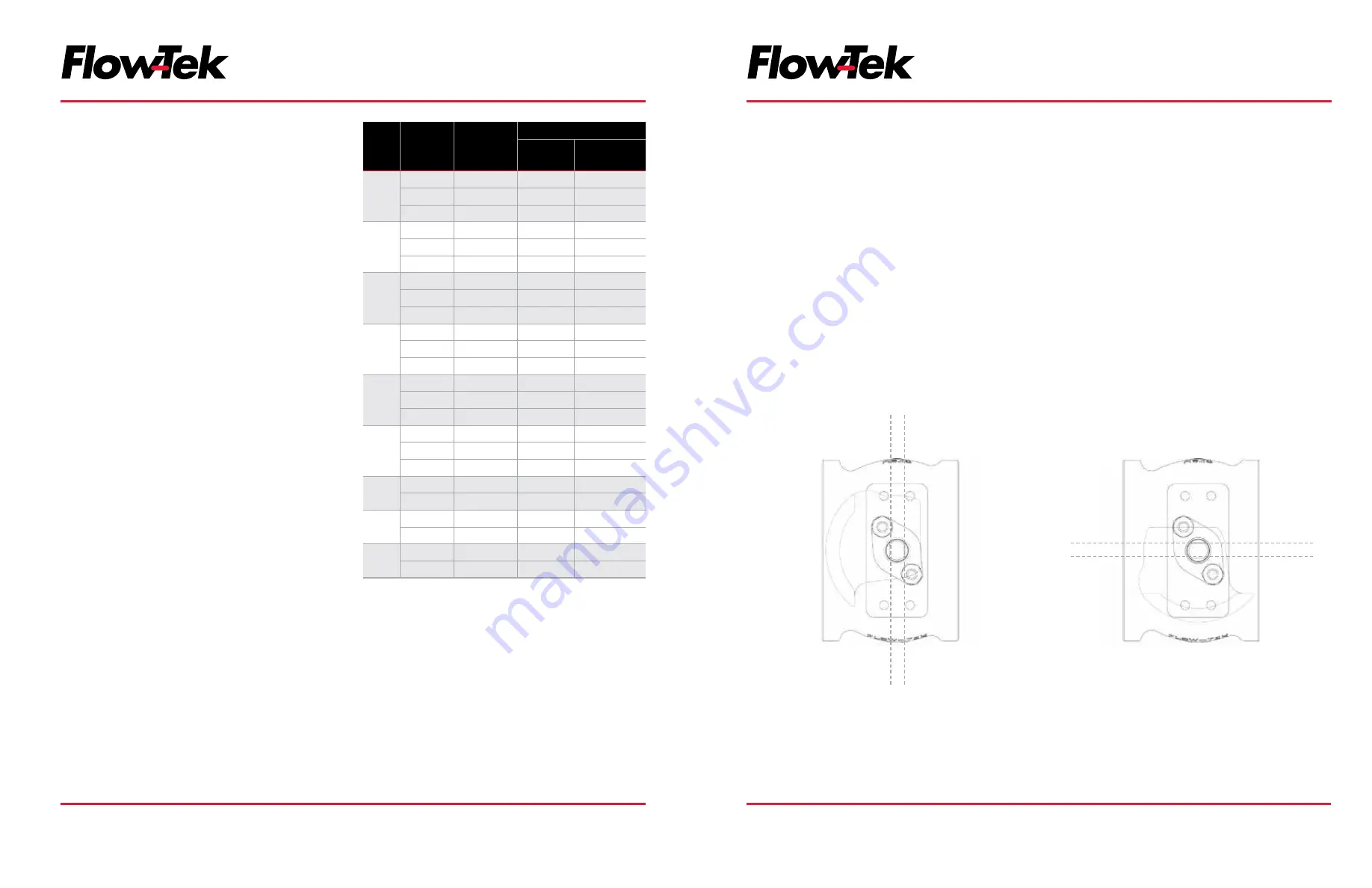

Table 1:

Flange Bolting Specifications

Size

(in)

ANSI

CLASS

RATINGS

Bolt Length

(mm)

(2)

Torque (N-m)

(1)

Low

Strength

Intermediate

Strength

1

150

65

31

82

300

75

63

165

600

90 / 80

(3)

63

165

1

½

150

70

31

82

300

90

110

295

600

110 / 90

(3)

110

295

2

150

85

63

165

300

90

63

165

600

110 / 95

(3)

63

165

3

150

90

63

165

300

110

110

295

600

125 / 110

(3)

110

295

4

150

90

63

165

300

115

110

295

600

145 / 125

(3)

179

478

6

150

100

110

295

300

120

110

295

600

170 / 150

(3)

270

720

8

150

110

110

295

300

140

179

478

10

150

115

179

478

300

160

270

720

12

150

120

179

478

300

170

401

1069

(1) Torque values are recommended for low and intermediate strength

bolting per ANSI B16.5 ¶5.3.2. Higher torques may be used with high

strength bolting (ANSI B16.5 ¶5.3.1). In all cases the user must verify the

selected bolting‘s ability to seat the joint under expected operating condition.

Long thru-bolted joints generally require higher strength bolting and torque

values than shorter flanged bolting depending on operating conditions.

(2) Lengths are based on ANSI B16.5 stud bolts and raised face ends.

(3) Lengths are for the shorter studs used in treaded holes. Refer General

Assembly drawing for the quantities.

7. REMOVING VALVE FROM LINE

1. If an internal problem is suspected with the valve and

disassembly is required, remove the valve from the line

by proceeding as follows.

WARNING:

Depressurize line to atmospheric pressure,

drain all process fluids and decontaminate the valve (if

caustic or hazardous materials are present). Failure to

do so can cause serious injury. Make sure the valve is in

closed condition.

2. Attach a hoist or some means to support the valve.

3. Remove line bolting. Do not attempt to pry line flanges

apart by pushing or pulling on the valve or actuator.

4. Slide the valve carefully from the line. To avoid damage

to the gasket surfaces, do not twist the valve.

5. After the valve is completely removed from the line,

slowly relieve air pressure from the actuator.

8. ACTUATOR

The valve closed and open position are indicated by the

position of double “D” on the stem. Refer below figure.

If possible, install the valve so that the actuator can be

disconnected without removing the valve from the piping.

The actuator must not touch the pipe line, because pipeline

vibration may damage it or interfere with its operation.

In some cases, for instance when a large-size actuator is

used or when the pipe line vibrates heavily, supporting the

actuator is recommended.

Figure 1

CLOSED

CLOSED

OPEN

OPEN