Printed in Canada

June 14, 2007

Section 2 - Hydraulic Fan Group

01523r7.wpd

Page 2-9

D.

Once fan starts reversing pitch, time a full pitch

reversal, it should not be less than

1 sec.

.

If the cycle is too long, drill out the orifice. If the cycle

is too short a smaller orifice is required. Contact your

local hydraulics supplier or Flexxaire

®

for orifice.

E.

Toggle the Air Flow Switch to change air flow to

the desired direction. Ie.: sets whether the fan acts

as a sucker or blower.

F.

Check the Purge button. This button when pressed

temporarily turns off the timer and when released

the timer starts up and does a purge for the

duration set on the “ON TIME”.

G.

Set the Timer by adjusting the “ON TIME”

(Duration) and the “OFF TIME” (Interval) to the

desired lengths. Select a duration and interval that

meets the application requirements . If unsure, set

“ON TIME” to 15 seconds and “OFF TIME” to 20

minutes.

NOTE 1:

“ON TIME” is the length of the purge

cycle (duration) and is adjustable

between 1-100 seconds. “OFF TIME”

is the time between purge cycles

(interval) is adjustable between 1-100

minutes.

NOTE 2:

This Timer gives the option of setting

interval times as low as 1 minute, but

it is not recommended to set intervals

below 5 minutes due to reduction in

cooling capacity and potentially

excessive wear of fan components.

H. Step only applicable for 3-Position control kit.

Remove jumper from temperature switch leads and

the fan should return to NEUTRAL pitch if engine

is cold.

NOTE:

The return to NEUTRAL pitch is

accomplished due to the centrifugal forces

from the spinning blades. At low idle, it

may take longer to return to NEUTRAL

pitch as the forces are not as great as at

high idle.

I.

Step only applicable for 3-Position control kit.

Warm up engine until the fan goes into pitch.

Ensure the engine temperature is not too high. If

engine gets too hot before fan goes into pitch; the

temperature switch is installed in a cold spot on the

engine block and a location closer to the

thermostat is required. If this is the only location for

the temperature switch then a switch with a lower

temperature rating is required. Contact your local

dealer or Flexxaire

®

.

NOTE:

By adding a jumper to the temperature

switch leads, the valve essentially

becomes a 2-Position valve with full

“PULL” or full “PUSH” and no NEUTRAL

position. Do this until the correct switch is

obtained.

2.2.2.7. FX Fan Operation

2-Position Valve Kit

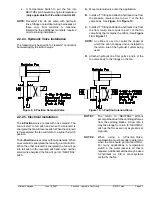

The 2-Position Solenoid Valve setup places the

fan into pitch in standard operating direction on

start up of machine. Purges occur at the preset

intervals for the preset duration. The manual purge

switch may be pressed at any time to initiate a

purge cycle. When the purge switch is pressed

and released, the fan will do a full purge cycle and

the timer will be reset. The next purge will happen

at the full interval from when the button was last

pressed. The air flow toggle switch may be used at

any time to reverse the pitch.

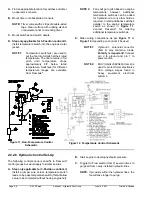

3-Position Valve Kit

The 3-Position Solenoid Valve setup puts the fan

into “NEUTRAL” pitch until engine temperature is

high enough to make the temperature switch

close. The fan will then go into full pitch in the

standard operating direction. If the engine

temperature drops (approximately 8

?

F), the

temperature switch will open and the fan will go

back to neutral pitch. Purges will occur at the

preset intervals when the fan is in full pitch (if the

fan is in neutral pitch, purges will not occur). The

manual purge button may be pressed at any time

to initiate a purge cycle. When the purge switch is

pressed and released, the fan will do a full purge

cycle and the timer will be reset. The next purge

will happen at the full interval from when the

button was last pressed. The air flow toggle switch

may be used at any time to reverse the pitch.

NOTE 1:

The Temperature switch disables the

solenoids when it is open (cold). This

prevents any purging: automatic or

manual. As well the toggle switch will

not reverse the pitch while the fan is

in neutral.

NOTE 2:

If multiple temperature switches are

used, then the fan will go to neutral

pitch when ALL switches are open. If

any switch is closed, the fan will go to

full pitch.

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...