Printed in Canada

June 14, 2007

Section 2 - Hydraulic Fan Group

01523r7.wpd

Page 2-3

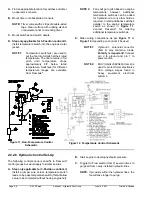

2.1. INTRODUCTION

This manual explains Flexxaire

®

’s FX series of fan

systems. The FX fan blade pitch is controlled

hydraulically through two hydraulic ports. These ports

supply fluid to a small double acting hydraulic cylinder

embedded within the mainshaft. Pressuring either

hydraulic port will move the fan blades into “PUSH” or

“PULL” positions, respectively.

2.1.1

.

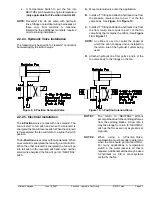

External Identifiable Components

The Hydraulic Fan Assembly can be identified by

several external major components in

Figure 1

. Use

this diagram for terminology and component

identification.

2.1.2. Blades

Typical service life for fan blades is 10,000 hours and

higher. Actual blade life is dependent on operating

conditions. High abrasive environments will subject

the blades to higher wear.

Figure 1, External Fan Assembly

96229r0

1. Hub Assembly

4. Hydraulic Connector

2. Blade Assembly

5. Fan Mounting Bracket

3. Pulley

6. Mainshaft Assembly*

*Serial number and Fan part number stamped on mainshaft.

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...