Page 2-6

01523r7.wpd

Section 2 - Hydraulic Fan Group

June 14, 2007

Printed in Canada

2.2.2.1. Hydraulic Specifications

Flexxaire

®

FX Fan assemblies are shipped with #4

ORB fittings with JIC (7/16" - 20 MALE 37

?

Flare end)

ends. The specifications below are required for the FX

fan system to operate.

Pressure Specification:

Flexxaire

®

fan requires a

source that operates between 300 and 1200 psi..

Operating pressures outside this range require

verification and acceptance from Flexxaire

®

Engineering.

Oil Specification:

The hydraulic seals used are very

compatible with most petroleum based hydraulic

and lubricating oils. Do not use high temperature

oils, aromatic solvents or industrial phosphate

esters; use of these fluids will require seal

replacement.

Interval Of Pitch Change:

The Flexxaire

®

fan should

be operated at a pitch change rate of not less then

1 sec.

.

Ie.: To go from full “PULL” to full “PUSH” (or

vise versa) positions must not be less then

1 second. An orifice in the hydraulic return

line is necessary to meet this requirement.

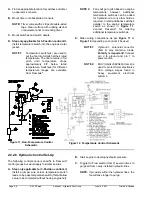

2.2.2.2. Selecting A Hydraulic Source

The Flexxaire

®

FX fan requires a hydraulic pressure

source from the machine. The source for your specific

application may be specified in the

Special

Instructions

under the title of “Recommended

Hydraulic Source” within the front cover page of this

manual. If not, there are several considerations:

A.

The fan uses a small hydraulic piston with a 1"

stroke. There is no “leakage” in the fan and it takes

very little flow to adjust the blade pitch (a couple

cubic inches (in³) of oil); thus, the fan puts very

little demand on a hydraulic system, and will not

affect most systems.

B.

The hydraulic source must have an acceptable

operating pressure.

C.

The hydraulic source must maintain the minimum

operating pressure to hold the fan blades in pitch.

NOTE:

The Differential Pressure (Source Pressure

minus Return Pressure) must meet or exceed

the minimum pressure requirement.

D.

Avoid hydraulic systems with high pressure spikes.

E.

The hydraulic source must have acceptable oil

types, refer to

Table 2, Page 2-10 - Approved

Oils and Service Properties

.

F.

Potential hydraulic sources/systems:

i.

Pilot / Charge pressure systems

ii.

Parking brake systems

iii.

Power steering systems

iv.

Final drive systems

v.

Any other hydraulic source that

meets the above specifications but

are not listed above may be a good

s o u r c e . C o n t a c t F l e x x a i r e

®

Engineering for verification.

G.

Once a suitable hydraulic source is selected. Find

locations to install “T” fittings in the pressure

(source) line and return tank line on this system.

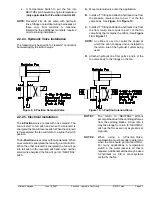

2.2.2.3. Control Kit Information

After the fan is mounted onto the machine, the

hydraulic solenoid valve, hydraulic lines, etc. must be

installed. The Flexxaire

®

FX fan can be controlled with

a

2

or

3

position solenoid valve, or a full variable pitch

controller. Please contact Flexxaire

®

Manufacturing

Inc. for documentation on the full variable pitch

controller.

A

2 position

valve gives two pitch positions - full

“PUSH” and full “PULL”, and is suitable for

applications which

only

require purging.

A

3 position

valve gives three pitch positions - full

“PUSH”, full “PULL” and “NEUTRAL”. In NEUTRAL

pitch, the fan does not blow air and over cooling

problems can be reduced (as well as an increased

horsepower and fuel savings).

The control components are not supplied with the

Flexxaire

®

FX fan. Customers may purchase their

own components or purchase one of two control kits

which are available from Flexxaire

®

.

2-Position Control Kit -

P/N 12528

3-Position Control Kit -

P/N 12529

Flexxaire

®

control kits include the following

components:

i.

A Timer to automate purge cycles.

ii.

A Toggle Switch to set air flow direction for a

sucker or blower fan.

iii.

A Hydraulic Solenoid Valve, orifice and

fittings for the valve: to position fan blades.

iv.

A Momentary Switch to trigger manual purge

cycles.

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...