www.flexco.com

—6—

C

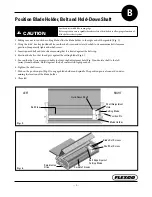

Test Skive

!

CAUTION

For multiple skives, use of power drill is recommended to avoid fatigue from use of ratchet.

Operate only with clamping lid in place and fully closed.

Use hand drill with a clutch mechanism set to the minimum required to skive the belt.

Do not exceed 600 rpm when skiving.

Do not permanently affix a motorized drive device to this equipment.

1. Keep hand on closed lid to ensure adequate clamping force and to hold the skiver in place while skiving.

2. Use a hand-held power drill with a 1/4" extra deep bit on the spindle hex drive to rotate the spindle and skive the

belt (Fig. 4). A ratchet can be used in place of the drill.

3. Position the belt so that the edge is against the cutting blade (Fig. 4)

4. Measure the skived belt thickness.

5. Using the 3/32" hex key loosen blade set screws on top of blade holder.

6. Using the 5/32" hex key remove the shim screw and shim storage cover located on the right side plate to access the

shims (Fig. 5).

7. Insert the required number of shims under the blade to prevent belt carcass damage. Each shim is 0.010" thick, so

addition of each shim will result in the skived belt thickness being 0.010" thicker.

8. Tighten blade set screws.

Fig. 5

Shim Storage Screw

Shim Storage Cover

Right Side Plate