—3—

Baler Belt Skiver

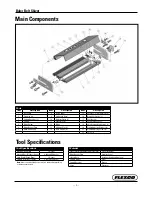

Main Components

Tool Specifications

Tool Specifications

Maximum Belt Width

7.5 inches

Unskived Belt Thickness Range

0.200 to 0.400 inches

Skive Depth (Reach Back)

1.0 inches

Skived Belt Thickness Range

0.190 to 0.240 inches

Note:

Other skived belt thicknesses may be achieved by providing

a shim beneath the belt.

Material

Side Plates, Blade Holder, Adjuster Plates

Zinc-Plated Steel

Blade Backer Plate

Stainless Steel

Lid and Base

Hard Coat Anodized Aluminum

Spindle, Blades

Steel

Spindle Bushings

Bronze

Shims

Polyester

Parts

Item

Description

Item

Description

Item

Description

1

Base Plate

8

Flexco Label

15

Position Pins (not pictured) (2)

2

Clamping Lid

9

Cut Hazard Decal

16

Blade Set Screws (2)

3

Spindle Bushings (2)

10

Adjuster Plates (2)

17

Shaft Screw

4

Spindle

11

Side Plates (2)

18

Shim Storage Cover

5

Blade Holder

12

Blade

19

Shim Storage/Stop Screws (2)

6

Blade Backer Plate

13

Lid Hinge Pins (2)

20

Clamp Adjusting Washers (4)

7

Hold-Down Shaft

14

Base Screws (6)

21

Clamp Adjusting Screws (4)

22

Shims (5)