27

26

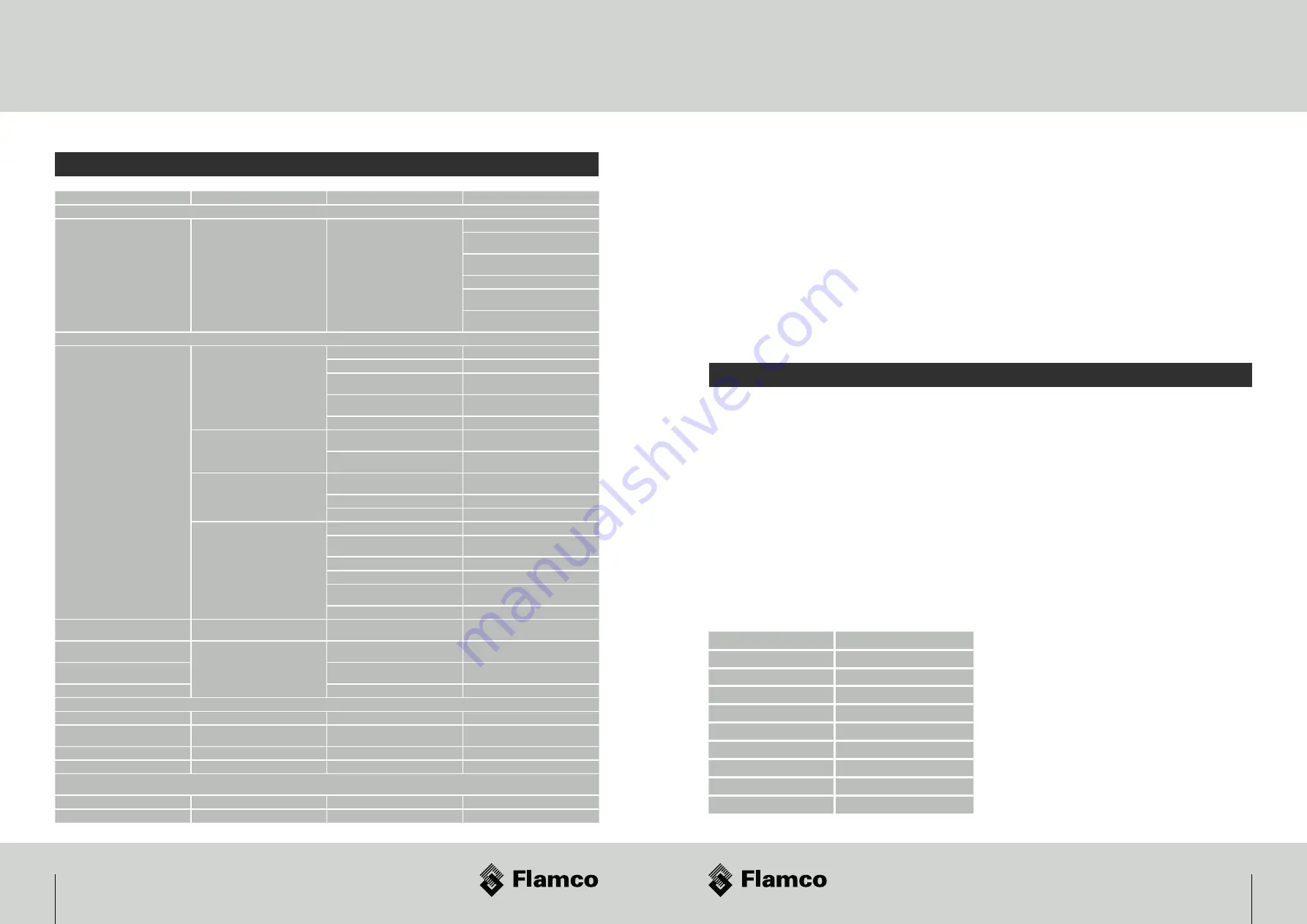

7.12 Troubleshoot (technician)

7. Service

Complaint

LED indication light

Cause

Solution

No DHW

No DHW

No water pressure

Check/open main water supply valve

# &ޕ*2- ./-$/*-!*-*-- /)+-*+ -

placement

Flow restrictor is clogged or jammed. Replace

ޕ*2- ./-$/*-

'*2. ).*-$.'*"" ѵ +' ޕ*2. ).*-

DHW heat exchanger is clogged. Replace DHW

heat exchanger

Check valve is jammed. Replace check valve

housing including the check valve

DHW not at the right temperature

DHW does not warm up

LED does not light up

HIU is not connected to power source

Connect the HIU to the power supply

No power at power source

Check power source

Power cables not properly connected to

electronic regulator

Connect the power cables to the electronic

regulator

Fuse is broken

Check for any short-circuit problems and

replace fuse (3A)

Failure in electronics

Contact your supplier

- )ޕ.#$)"

Tapping threshold is to low, minimal 1 L/min.

has not been reached

Increase tapping to at least 2 L/min. by opening

the tap further

Flow sensor is not installed correctly

# &ޕ*2. ).*-Ѷ- +' ' *-- +'

ޕ*2. ).*-

ޕ.#$)"

Sensor(s) are not connected or lose contact

Check loom connections and connect the

sensors properly, then restart electronics

Sensor(s) defect

Replace broken sensor and restart electronics

Possible defect electronic cables or electronics

Contact your supplier

Supply and return valves are closed

Open supply and return valves

Pressure or temperature of the DH system are

)*/$)*-) 2$/#.+ $ޔ/$*).

Check temperature and pressure of the DH

system

Filter is clogged

# &)' )ޔ'/ -

DHW heat exchanger is clogged

Replace DHW heat exchanger

Cables of the control valves are mixed up

Connect cables properly. Green connector must

be connected to the DHW control valve

Possible defect in control valve

Replace control valve

Option: DHW circulation circuit does not

warm up

LED does not light up

Fuse is broken

Check for any short-circuit problems and

replace fuse (3A)

Power supply cable of the optional DHW

circulation pump unit is not connected

Connect the power supply cable of the optional

DHW circulation pump unit

Optional DHW circulation pump unit is broken

or jammed

Replace DHW circulation pump unit

Failure in electronics

Contact your supplier

Casing will not close properly

Casing does not close properly

Cables are caught in between unit and casing

Keep cables free of any obstructions

Metal bracket holding the heat meter is not

ޔ// *-- /'4

%0./ҝޔ/-& /)/-4"$)

Heat meter is obstructing the casings path

Connect the heat meter properly

Electronics are not properly placed

Check mounting of electronics

Other defects

It is normal for the HIU to generate a light noise during tapping or heating operation. The regulator valves can also make a light humming sound

Rattling sound

*-"- )ޕ.#$)"

Flow sensor not installed correctly

)./''ޕ*2. ).*-+-*+ -'4

Other defects

Contact your supplier

Guidelines for System Conditioning of Heating and Cooling Networks for Flamco Limited - LogoEco Heat Interface

Units (HIU)

Flamco Limited prides itself on bringing to the UK market a proven range of Heating and Cooling Interface Units. To ensure

/#/*0-+-*0/. '$1 -$)- . '*)" 1$/4)+ -!*-() Ѷ/# . "0$ '$) .- .+ $ޔ''42-$// )/*$) ).0-

both the primary and secondary side of the heat network are designed, installed and commissioned to realise the desired

heating comfort levels.

# . "0$ '$) .- )*/*Ȃ - !*-0. *)+*/' Ѷ*( ./$Ѷ)2/ --2*Ȃ.$ *!

/# .4./ (ѵ*' '4!*-/# # /$)")**'$)"$-0$/.ѵ*-!0-/# -"0$) *)2/ -/- /( )/)2/ -

)'4.$.+' . - ! -/*сшҝспрсѶфпҝспрт)чффсѵ

#$'./)*/ 3#0./$1 Ѷ2 *Ȃ -/# . "0$ '$) .

from experience and a practical standpoint, in addition, as a check list to support design review. These guidelines are not

$)/ ) .()/*-4*-ޔ3 $)/# $-++-*#Ѹ(*- *1 -/# 4- $)/ ) ..0++*-/$)"*0( )//$*)/*#$"#'$"#/

good practise and methodology ensuring operation and maintenance activities are kept to a minimum post handover. We

are not specialists in the design, installation and or cleaning and subsequent treatment of water systems but, nevertheless,

contained in the sections below are importance aspects to consider.

8.1 System Design Considerations

• A review of the system should be undertaken post the design stage. The review should focus on the installation,

'*/$*))+$/4*!./-$) -.*/#ޔ3 )/ (+*--4Ѷ$-)".- (*1' 1$ .Ѷ -$./-+.Ѷ$.*'/$*)

valves to ensure that removal of debris from the system which was not removed in the commissioning activity is

managed and that sub sections can be economically isolated to permit maintenance.

• It should be considered at the design stage to include into the design a means ferrite removal. Poorly commissioned

and maintained systems exhibit corrosion. As the majority of systems contain products manufactured from iron, it is

the iron in the form of steel ferrite which creates the tell tale black sludge or blacked water which indicates corrosion

is taking place of components of the system. This corrosion if remaining unchecked, fouls water ways and controls,

erodes system components, reduces system performance and leads to the production of hydrogen in the system

known as “Gassing”. This is also a tell tale sign of system corrosion.

•

.*1 -шпڿ*! -$.$).4./ (.$.! --*0.2 - *(( )/# $)./''/$*)*!-- -/#Ѷ(") /$ޔ'/ -/**/#

remove the ferrite but act as a means of identifying corrosion is taking place and a prompt for remedial action.

•

# - (*1' 1$ $ ''4Ѷ.#*0'#1 ޔ-./+..-/ *!цфڿ -$.- (*1'*-"- / -Ѷ#1 $)*-+*-/ $)/*

$/.//$($3$)"!0)/$*)/**+ )/# .4./ (ޕ0$/*+ -($/-+$- (*1'*!/# -$.Ѷ(*0)/ $)/# *((*)

- /0-)Ѷ($)- /0-)+$+ 2*-&ѵ# ޔ'/ -.#'' *! ,0/ .$5 )+$/4/*''*2.0Ȃ$$ )/ޕ*2-/ )

-$.+/0- !*-/# .4./ (.$5 җ'$) .$5 $.- *(( ) Ҙѵ)4.0#ޔ'/ -.#*0'#1 /# !*''*2$)"(") /$

ޔ './- )"/#+$/4.($)$(0(/* ).0- (3$(0(! --$/ - (*1'ѵ

8. Appendix A

# ޔ'/ -.#*0' /*/# - ,0$- ( )/.*!/#

“Operating and Maintenance” instructions handed over with

/# .4./ (ѵ!)1$.*-4./$& -$.+-*1$ 2$/#/# ޔ'/ -$/

should be attached at a suitable location as to indicate the

+- . ) 2$/#$)/# .4./ (*!/# ޔ'/ -/* ).0- + -$*$

checking & servicing by any attending Service Engineer.

2*0''.*- *(( )/#//# . ޔ'/ -.$)*-+*-/

sight glass, particularly on the larger sizes to provide a visual

means of assessing corrosion without the need to disrupt

the operation of the system for checking.

Line Size

Magnetic Field Strength

DN15

7500 gauss

DN20

9000 gauss

DN25

10500 gauss

DN35

21000 gauss

DN40

21000 gauss

DN50

52500 gauss

DN80

73500 gauss

DN100

73500 gauss

DN150

94500 gauss