C1 Controllers and Transmitters

Instruction Manual

September 2009

30

7. Attach the replacement relay and new relay

gasket with machine screws inserted through the

back of the case. Reinstall the output or supply

gauge.

8. Connect the tubing, and check all connections for

leaks. Perform the appropriate calibration

procedures.

Changing Output Signal Range

Use the following information and subsequent

procedures when changing the output signal range

of the controller or transmitter. Use the following

procedure:

D

For a controller or transmitter, use this

procedure to change from a 0.2 to 1.0 bar (3 to 15

psig) to a 0.4 to 2.0 bar (6 to 30 psig) output signal

range or vice versa.

D

For a differential gap controller, use this

procedure to change from a 0 and 1.4 bar (0 and 20

psig) to a 0 and 2.4 bar (0 and 35 psig) output signal

range or vice versa.

D

When changing the supply pressure source to

a new range, refer to table 5 for supply pressure

requirements for the output signal range selected.

Also, make appropriate changes to the nameplate of

the controller or transmitter, reflecting the new range

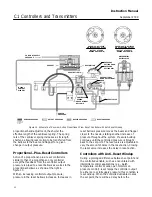

selections. Refer to figure 23 or 24 for key number

locations unless otherwise directed.

1. Shut off the supply pressure and process lines to

the controller or transmitter.

2. Disconnect the tubing from the mounting base

(key 57) and calibration adjuster (key 36).

Disconnect the tubing that connects the pressure

block (key 10, figure 21 or 22) to the Bourdon tube

or bellows assembly (key 5 or 52), at the pressure

block end.

3. Unscrew the machine screws (key 41, figure 21

or 22), and remove the subassembly from the case.

4. If the controller or transmitter uses a Bourdon

tube sensing element disconnect the Bourdon tube

from the beam (key 39) by removing the screw

(key 56). Be careful to avoid losing the bearing

(key 31). Unscrew the machine screws (key 55)

and remove the washers and Bourdon tube (keys 45

and 5).

5. Unscrew the bellows screws (key 53) from each

end of the mounting base (key 57).

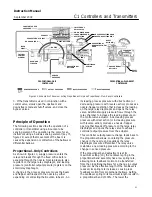

O

−

RING

(KEY 77)

A6281

−

1 / IL

Figure 20. Bellows Screw Detail

Note

The bellows screws (key 53) have an

O

−

ring (key 77, figure 20) installed

beneath the bellows screw head.

Remove the O

−

ring and obtain a

replacement when re

−

assembling the

bellows.

6. Unscrew the spring adjustor (key 65). Unclip the

lock spring (key 72, figure 18) and remove the

indicator scale (key 69) and the proportional band

adjustment knob (key 73).

7. Compress the bellows (key 52) so that the end of

the bellows, beam (key 39), and cantilever spring

(key 8) can be removed from the mounting base

(key 57).

8. Unscrew the bellows (key 52) from the

bellows/cantilever assembly.

9. Remove the cantilever spring from the spacer

(key 34).

a. Remove the beam machine screws (figure 19,

step 4).

b. Remove the cantilever machine screws

(figure 19, step 3).

c. Remove the inner flexure (figure 19, step 1)

and install it on the new cantilever.

10. Install the new cantilever spring (key 8) and

reconnect the beam (key 39) to the bellows spacer

(key 34) in reverse sequence of steps 9a. and 9b.

and reattach the bellows to the beam/cantilever

assembly.

11. Compress the bellows and install them into the

mounting base (key 57). Align the cantilever spring

with the gain adjustment bar (key 63). Install the

indicator scale (key 69) and the proportional band