Type 9500

7

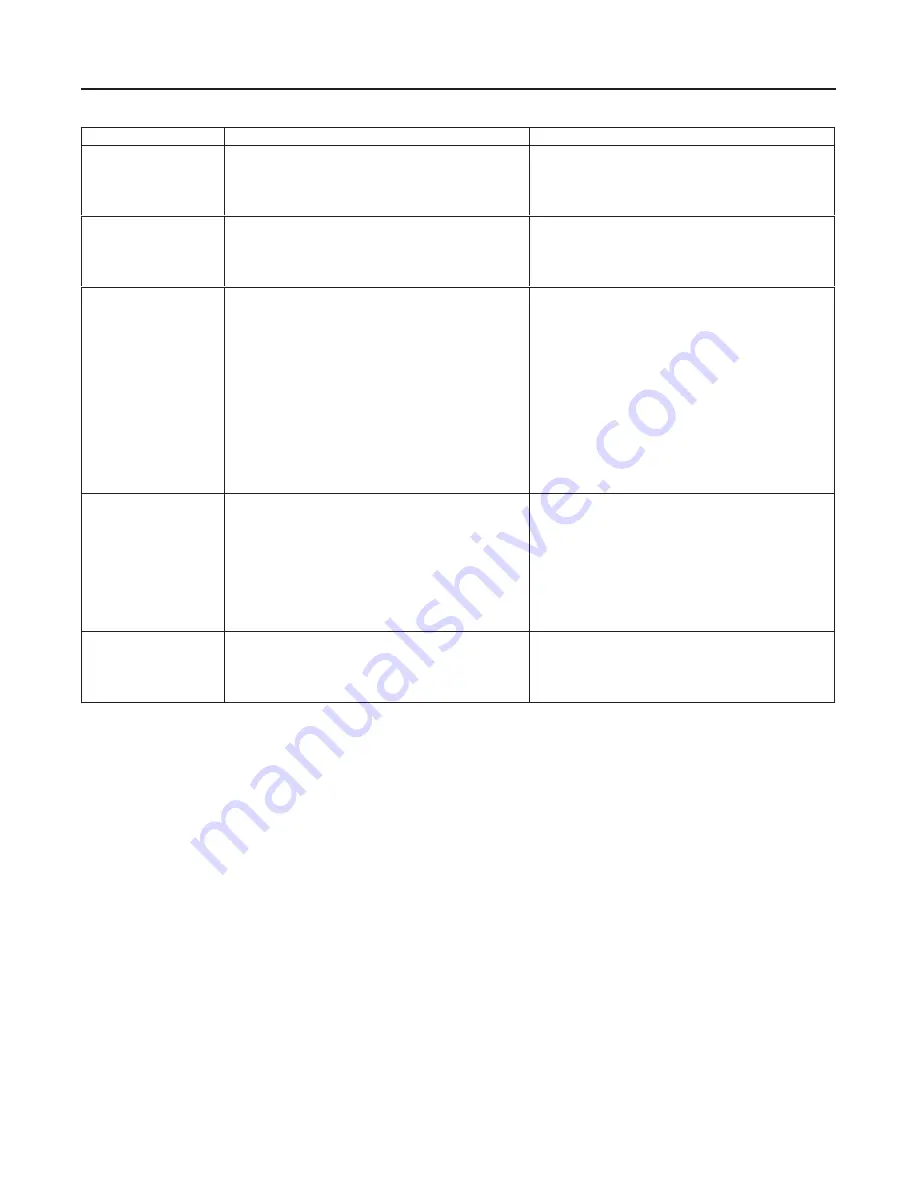

Table 3. Troubleshooting Guide

Fault

Possible Cause

Correction

1. Leakage out sides of

valve (at thrust plates)

between thrust bushings

and shaft.

a. Hub seals require adjustment.

b. Taper pins are not sealed.

a. Adjust using Hub Seals portion of Adjustments

procedures.

b. Remove valve from line and re-seat taper pins or install

new taper pins using Maintenance procedures.

2. Leakage out sides of

valve (at thrust plates)

between valve body and

thrust bushings, leakage

at flanges, faces, or both

a. Flange gaskets used.

b. Partial O-ring bead on liner faces damaged.

a. Check to see if flange gaskets are being used; if so,

remove gaskets.

b. Replace liner using Maintenance procedures.

3. Leakage through

disk/liner seal

a. Hub seals require adjustment.

b. Linkage requires adjustment.

c. Actuator has insufficient torque output to close disk

against pressure drop. (Actuators are selected to have

sufficient torque output to shut off the flow against a

specific pressure drop, not necessarily against the

maximum allowable pressure drop. Be sure that the

pressure drop for which the actuator is selected is not

being exceeded.)

d. Liner has been damaged by flowing medium or other

valve parts damaged by being subjected to service

conditions beyond those for which valve is designed.

a. Adjust seals using Hub Seals portion of Adjustments

procedures.

b. Refer to Linkage portion of Adjustments procedures.

c. If possible, check shutoff at lower pressure drops. If

shutoff is obtained at low pressure drops, but actuator

stalls and does not produce full disk rotation at service

pressure drop, actuator output torque is too low. For piston

actuators, it may be possible to increase output torque by

increasing supply pressure. Do not exceed maximum

allowable supply pressure of actuator.

d. Inspect and replace parts using Maintenance

procedures.

4. Valve shaft will not

rotate

a. If actuator does not stall, but shaft does not rotate, the

spline teeth on the valve shaft are sheared.

b. If actuator stalls, shaft is binding in bushings due to

linkage misalignment caused by excessive wear of linkage

parts.

c. If actuator stalls and linkage is not misaligned, actuator

may have insufficient output torque to rotate disk against

flow.

a. Refer to the actuator instruction manual to remove

actuator cover plate. Replace valve shaft using

Maintenance procedures if spline teeth are sheared.

b. Replace linkage parts.

c. Check actuator operation with no pressure applied to the

valve. If valve now functions properly, actuator is too

small.

5. Valve shaft rotates, bur

valve does not control

process fluid

Taper pins (or drive shaft spline for coated-disk

constructions) have been sheared due to obstruction to

disk rotation or other internal parts damaged by being

subjected to service conditions beyond those for which the

valve was designed..

Inspect and replace parts using the Maintenance

procedures.

7. Remove disk from valve body.

8. Remove liner (key 2) from valve body.

Some Type 9500 valves have the liner bonded to the

valve body. If the valve has a bonded liner, burn or

chip out the liner.

To strip the liner out with solvent, use Eccostrip 57,

Houghto Clean 224, or equivalent solvent. Cover the

valve with solvent bath or enclose the solvent bath

around the liner. Remove all adhesive after the liner

has been removed.

Reassembly

Before reassembling the valve, clean and inspect all

parts. Key number locations are shown if figure 7. Refer

to the

Parts List section to obtain replacement parts.

1. Insert liner (key 2) into valve body. A small amount

of silicone grease applied to the outside surface of the

liner will aid insertion of the liner. However, do not use

grease if the valve is to be used for oxygen service.

In vacuum service applications, upon customer re-

quest, you may use Eccobond 285/24LV bonding

agent (part no. G1414006992) to bond the liner to the

valve. Though bonding is not required use the lettered

steps below when bonding the liner to the valve body .

If a different agent is to be used, follow instructions

furnished by the bonding agent manufacturer. In ab-

sence of instructions, consult your Fisher Controls

sales office or sales representative.

a. Roughen bonding surface of liner with a stiff

wire brush. De-grease bonding surfaces of liner

and valve body with solvent.

b. Mix the two epoxy components thoroughly and

spread a thin coat [approximately 0.015 inches