FIRST STOP SAFETY

9

Environment

The location of equipment will have a bearing on the frequency of testing.

For example an item that is used in a low-risk environment such as an office

will have a much lower risk of damage than an item used on a construction

site. Please see below for various examples.

Low risk: Offices, shops, hotels and nursing homes

Medium risk: Schools

High risk: Factories, commercial kitchens and equipment used by the public.

Very high risk: Construction sites

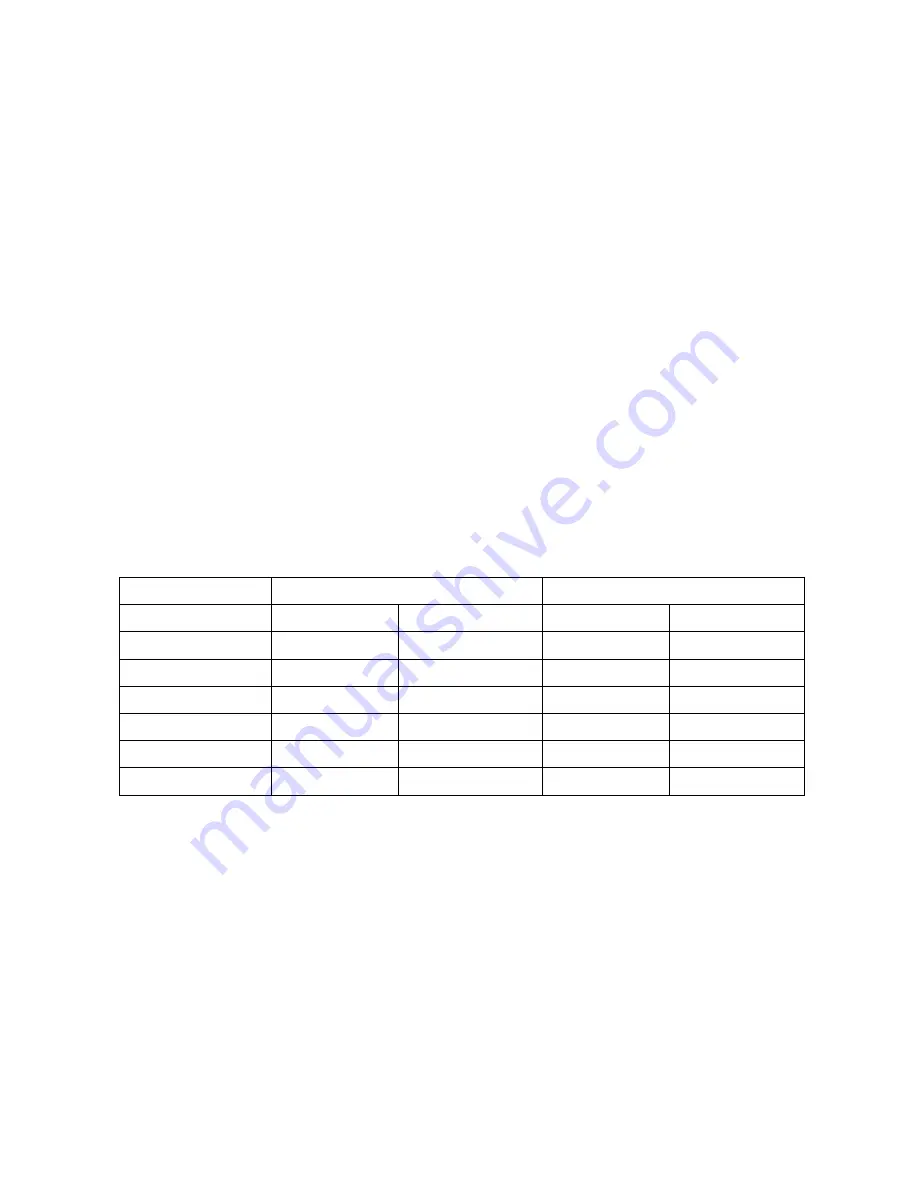

Frequency of visual inspection and testing

It is not essential to carry out inspecting and testing every year. Table 1 below

gives some intervals that are recommended in low risk environments, such as

offices, shops, hotels, and nursing homes. (Timescales for other environments

can be found in Appendix I)

Class I

Class II

Type

Inspection

Insp. & test

Inspection

Insp. & test

Stationary

24 months

60 months

24 months

none

IT

24 months

60 months

24 months

none

Movable

12 months

24 months

24 months

none

Portable

12 months

24 months

24 months

none

Hand-held

12 months

24 months

12 months

none

Table 1: Frequency of inspection and testing in low risk environments

Equipment Register

This form is used to list all the electrical equipment in the business.

Information, such as Class I or II, type of equipment and frequency of test is

recorded. A blank form is supplied, and this can be photocopied and used if

additional sheets are required. As new equipment is purchased, this needs to be

added to the register.

BattPAT

Issue 2.