4

© 2021 Carrier

-

for the high tension igniter (HTI): this type of device creates an electrical arc of low energy which allows for

ignition of a gas/air mixture in clean environment and repeatable conditions. The secondary circuit voltage is 8

000 VAC at primary supply 230VAC or 110 VAC.

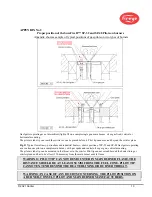

Both High Energy Spark Igniter and High Tension Igniter rods should be fitted the way that the tip end should be

placed at a distance of ~10 mm back from the stabilizer plate (see Fig. 1).

It should be noted that the rod tip positioning against the stabilizer in the pilot gas part assembly (pos. 1 on Fig.

1) should be done outside the air tube only (do not install the rod in the gas head already mounted in the air

tube). Only after proper rod positioning, should the rod be fixed by tightening the rod holding gland and the

whole gas assembly with igniter rod inserted into the air tube pos. 4.

The rods of both types of devices are mounted in gas head by means of a holding gland 1/2"BSP.

The ignition device is not in gas igniter scope of supply. It is normally specified and ordered separately.

5.

TECHNICAL DATA

Fuel: two standard versions for Natural Gas (NG) and for Propane Gas or LPG (PG) - see gas characteristics in

Appendix 1. In case of other fuel gas needed see p. 11 Ordering Information Special Pilots and Appendix 3.

Outer diameter of the air tube

32.0 mm

Outer diameter of the mounting tube

38.0 mm

Outer diameter of the ignition rod

16.0 mm

Capacity range:

Natural Gas

19 ÷ 37 kW at 20 ÷ 80 kPa - see capacity vs. pressure graph in Appendix 1

Propane Gas

28 ÷ 52 kW at 20 ÷ 80 kPa - see capacity vs. pressure graph in Appendix

1 - in case of other capacity range needed - see p. 11 for Special Pilots

Air flow

max. ~ 30 m3/h – adjust to capacity as in p. 8.11

Air pressure range

0.5-1.0 (max. 1.2 kPa)

Air connection

3/4" BSP (inner thread)

Gas connection

1/2" BSP (inner thread)

Operating temperature

max. continuous 300°C, orifice-stabilizer, end of gas and air tube 500°C

Igniter rod reference length range “L” 0.5 ÷ 3.0 m - longer upon request

Pilot weight: P/N

SP-32

-

NG/PG

-

FD-0.5

(length L=0.5 m): 2.13 kg, pilot weight adder: approx. 1,50 kg/m

Material used for pilot construction

all parts: 304/316 SS and heat-resistant steel 310/330 SS

Notes

:

1. If the above parameters are different than those required please contact Fireye

2.

For Imperial Units please refer to the Appendix 4 Unit Conversion Table

3.

Device complies with the requirements of the European Directive 2011/65/EU (RoHS 2)

6.

OPERATIONAL SAFETY

When operating and handling the pilot burner please follow the rules below:

6.1 Use pilot only for its intended purpose.

6.2 At the time of installation, operation and maintenance follow the procedures described in the instructions

and documentation of the pilot, ignition device and the main burner.

6.3

Check environmental conditions and ensure that the specified operating temperatures of pilot and

igniter components will not be exceeded

(

see p. 5 and igniter Manual).

6.4 Follow the warnings contained in the documentation.

6.5 Do not make any modifications or changes to the pilot construction.

6.6 Before starting, make sure that all parts of the pilot and electric ignition device are in good condition.

6.7 Circuits of power packs as well as igniter rods, enclosures and junction boxes must be properly grounded.

6.8 Before igniting, check the tightness of gas tube connections.

6.9 During the observation of the pilot flame wear special goggles to protect the eyes from UV flame radiation.

6.10 Do not remove the protective ground when the ignition device is energized.

6.11 Before working on the ignition device, ensure the power is disconnected.

6.12 Before maintenance or repair works check that the gas shut-off valve is closed.

6.13 During installation, start-up or maintenance works on the pilot or burner/ heater always wear protective

clothing and use protective gloves.