®

9

10.1 INSPECTION AND MAINTENANCE

SP-32-

NG/PG-

ND

pilot because of simple design does not require complicated maintenance procedures.

Checking and cleaning of air and gas tubes:

a)

Close the manual gas valve and disconnect the pilot gas line.

b)

Disconnect the ignition rod electric supply cable.

c) Unscrew the mounting ring.

d)

Loose the adjusting sleeve locking thumb screw as it may block the stabilizer plate during slide out. Then

carefully slide out the gas part assembly from the air tube.

e) Check the ignition rod at least every 12 months. For checking and standard service do not remove the rod

from the gas part. Follow the igniter User’s Manual.

Pull out

the electrical igniter only if it is absolutely necessary e.g. when rod is worn or damaged and has to

be repaired or replaced. Before that, loose the ignition rod holding gland and then follow p. 7.2.

Unscrew the rod tip before pulling out rod from the gas part and holding gland for easier slide without any

jamming.

f) Check and clean the bleed and main orifices. For cleaning use a soft copper wire.

g)

To remove heavy dirt use a soft wire brush e.g. copper wire brush.

h)

Blow compressed air through the whole gas part assembly.

i)

To check the air tube condition loose the mounting tube clamp assembly screws and pull out air tube.

Check for overheating traces and clean it.

j)

Assemble all the elements back to obtain the original configuration.

Checking of ignition device:

k)

C

heck the complete

ignition device at least every 12 months. Follow instructions in its User's Manual.

10.2 TROUBLESHOOTING

If the gas pilot does not operate correctly check the following:

a)

All manual gas valves on gas supply line were open and there is gas available.

b)

All valves in the supply line are functioning properly.

c)

The preset gas pressure is correct.

d)

Is there a significant influence of external conditions on the amount of air supplied to the pilot.

e)

Gas supply lines are clear - check strainers.

f)

Bleed and main orifices in orifice-stabilizer assembly are clear

.

g)

Electric ignition device is working properly and its rod correctly positioned in gas part assembly.

If it is not working properly - follow the ignition device manual.

h)

The power parameters for ignition device are correct.

If the gas lights but the flame is unstable, or goes out when main burner goes into operation, check that:

i)

The gas pressure does not drop during pilot light-off (trial for ignition).

j)

There is no significant interference of the air flow around the pilot

k)

The air from the main burner does not blow off the pilot flame or does not move it out of the field of view

of the flame scanner (if applied).

l)

Flame safeguard system works correctly and the flame is not obscured.

Improper operation of the whole installation requires the detailed checking of the power line and all

components, including any temporary use of override switches or jumpers.

Be aware of all connections to be later restored to normal state, to allow safe operation.

11. SPARE PARTS, WARRANTY CONDITIONS

11.1

For start-up and warranty period it’s recommended to order following spare parts in quantity as below:

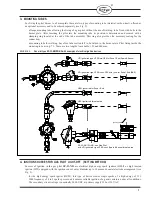

- a set of loose parts used on both sizes on pilots:

SP-32

and

SP-48

(see Fig. 5) - one for 4 pilots

- complete orifice-stabilizer assembly for

SP-

32-

ND

pilot,

including:

- on

e for 4 pilots

nipple with bleed and main orifice, mounting bracket, stabilizer