LEARNING TO WELD

Whether you have welded before or not, it is important that you become familiar with your new welder, its

controls and the results achieved at different settings. We strongly recommend that you practice with your new

welder on scrap metal. Try different heat settings, base metal thicknesses and welding positions for each type

and size of wire that you will use. By practicing, you will gain a feel for how changes in these welding vari-

ables affect the weld.

If you have not MIG welded before, you need to develop welding skills and techniques as well.

The self-taught welder learns through a process of trial and error. The best way to teach yourself how to weld

is with short periods of practice at regular intervals. Practice welding on scrap metal that can be discarded. DO

NOT attempt to make any repairs on valuable equipment until your practice welds are of good appearance and

free of slag or gas inclusions. What you fail to learn through practice will be learned through mistakes and re-

welds later on.

HOLDING THE GUN

Hold the welding gun in the way that feels most comfortable to you. While practicing with your new welder,

try holding the gun in different positions until you find the one that works best for you.

Position the Gun to the Workpiece

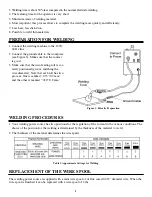

There are two angles of the gun nozzle in relation to the workpiece to consider when welding.

1. Angle A (Figure 8) can be varied. In most cases, the optimum angle is 60 degrees, the point at which the

gun handle is parallel to the workpiece. Increasing angle A increases penetration. Decreasing angle A

decreases penetration.

2. Angle B (Figure 9) can be varied for two reasons: to improve the ability to see the arc in relation to the

weld puddle and to direct the force of the arc.

The force of the welding arc follows a straight line out of the end of the nozzle. If angle B is changed, so is

the direction of the arc force and the point at which penetration is concentrated.

On a butt weld joint, the only reason to vary angle B from perpendicular (straight up) to the workpiece is to

improve visibility of the weld puddle. In this case, angle B can be varied anywhere from 0º to 45º. A 30º angle

works best.

On a fillet weld joint, the nozzle is generally positioned so as to split the angle between the horizontal and ver-

tical members of the weld joint. In most cases, a fillet weld is 45º.

Distance from the Workpiece

The end of the welding gun is designed with the contact tip recessed from the end of the nozzle and the nozzle

electrically insulated from the rest of the gun. This permits the operator to rest the nozzle on the workpiece

and drag it along while welding. This is helpful to beginning welders to steady the gun and allows the welder

to concentrate on welding technique. If the nozzle is held off the workpiece, keep a constant distance between

the nozzle and the workpiece and

DO NOT

exceed ⁄" or the arc may begin sputtering, signaling a loss in weld-

ing performance.

15

Figure 8: Gun Position, Angle A

Figure 9: Gun Position, Angle B

Summary of Contents for FP-90

Page 2: ......

Page 27: ...23 Figure 21 FP 90...

Page 29: ...25 Figure 22 FP 90 Wiring Diagram...

Page 30: ...26...