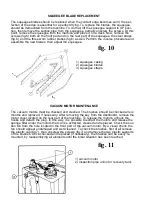

SQUEEGEE BLADE REPLACEMENT

The squeegee blades should be replaced when the contact edge becomes worn; the per-

fection of the edge is essential for a perfect drying. To replace the blades, the squeegee

should be demounted from the machine. To do that, lift the squeegee support in UP posi-

tion, then remove the suction pipe from the squeegee, partially unscrew the screws. At this

point, remove the squeegee from the machine and place it on a desk. Now, remove the

screws (fig.6) both on the front part and on the rear part of the squeegee, the steel straps

(fig.6), and the three worn rubber blades (fig.6) as well. Perform the inverse procedure and

assemble the new blades, then adjust the squeegee.

fig. 10

1) squeegee casing

2) squeegee blades

3) squeegee straps

VACUUM MOTOR MAINTENANCE

The vacuum motors must be checked and cleaned. The brushes should be checked all six

months and replaced, if necessary. After removing the key from the dashboard, remove the

motor cover located on the rear part of the machine. To release the motors, unhook the

hooks and detach the plug. In this way, it is possible to extract the motors and release the

sponge filter under the motors that can be extracted, cleaned and replaced. Check the suc-

tion fan from the hole located in the front part of the vacuum motor. By a visual check, the

fan should appear undamaged and well-cleaned. To check the brushes, first of all remove

the plastic cap (fig.7), then unscrew the screws (fig.7) and remove the two plastic supports

of the brushes. Once checked and replaced (if necessary), the brushes can be easily re-

mounted, by reassemblying all elements until the initial situation has been reached.

fig. 11

1) vacuum motor

2) inspection pipe union for recovery tank

Summary of Contents for I38UE

Page 9: ......