18

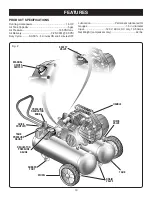

CHECKING THE OIL LEVEL

(1.) Place the compressor on a level even surface. (2.)

Remove the screw securing the dipstick and remove the

dipstick (Fig 13). (3.) Wipe the dipstick clean and re-insert

the dipstick making sure to push it all the way down. (4.)

Pull the dipstick out to check the oil level - Looking at the

dipstick the oil level should be between the two marks

Max and Min (Fig 14). If oil is low add oil USE ONLY SAE

40 NON-DETERGENT MOTOR OIL. Do not overfill. (5.)

Repeat steps 3 and 4. (6.) Install dipstick and secure with

screw.

SERVICE

This compressor is manufactured with a PERMALUBE oil

filled crankcase. Under normal operating conditions no

maintenance to the oil is required.

Fig. 13

Fig. 14

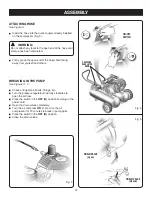

WARNING:

Hot surfaces. do not touch Hot Surfaces.

Allow compressor to cool prior to servicing.

CAUTION:

Use care to avoid tipping the unit over. Oil can leak and

damage can occur to the compressor or surrounding

items if the compressor is tipped over. In the event

oil lose has occurred, follow the instructions below

for CHECKING THE OIL LEVEL before operating the

compressor.

CAUTION:

Do not remove the oil from the crankcase. Operating the

compressor without sufficient oil will cause premature

compressor failure.

CAUTION:

Risk of unsafe operation. Overfilling with oil above

the MAX level will cause oil leakage and premature

compressor failure. Do not operate the compressor if oil

is filled above the MAX level on the dipstick.

Summary of Contents for HYPRO5-165

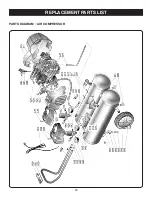

Page 20: ...20 REPLACEMENT PARTS LIST PARTS DIAGRAM AIR COMPRESSOR ...

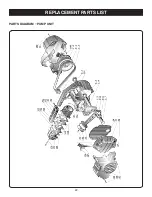

Page 22: ...22 REPLACEMENT PARTS LIST PARTS DIAGRAM PUMP UNIT ...

Page 25: ...25 ...

Page 46: ...20 LISTA DE PIEZAS DE REPUESTO DIAGRAMA DE LAS PIEZAS COMPRESOR DE AIRE ...

Page 48: ...22 LISTA DE PIEZAS DE REPUESTO DIAGRAMA DE LAS PIEZAS BOMBA ...

Page 51: ...25 ...