Revised 08/03

6

APPLICATION NOTES FOR TGS2611

2-6

Preheating of final assembly

To stabilize the detector assembly before gas

testing, the minimum period for preheating final

assemblies should be 48 hours at room

temperature (20~25˚C). Be certain to maintain

clean atmospheric conditions for preheating.

2-7

Gas test

Test all finished products in the target gas under

normal operating conditions. Keep the

atmospheric conditions in the chamber stable,

utilizing a user-defined standard test condition

which is based on applicable performance

standards and on anticipated usage for

detectors. Remove any traces of smoke,

adhesives, gases, or solvents from the chamber.

NOTE: Without testing after final assembly,

detectors have no guarantee of accuracy or

reliability.

2-8

Storage of finished products

Detectors should be stored in a clean air environ-

ment at room temperature. Avoid storage in

dirty or contaminated environments. Cautions

listed in Sec. 6-1.3 of “General Information for

TGS Sensors” should also be observed.

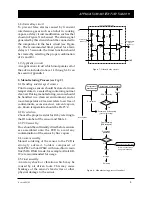

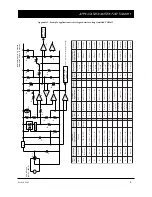

3. Anticipated Performance at 10%LEL of

Methane

When using the classified TGS2611 with Figaro’s

recommended R

L

for 10%LEL (Table 1) and

temperature compensated circuit design (Figure

2), typical alarm tolerances for 10%LEL of

methane such as those shown in Figure 9 are

expected. Each R

L

classification contains a range

of tolerance as exemplified by the alarming

range labelled as ‘standard conditions’ (i.e. these

conditions are well-controlled). When factoring

in the additional effects of environmental

extremes and the allowable variation in circuit

conditions, the resulting alarming range would

be typified by the range labelled as ‘operating

conditions’. However, in actual usage, alarm

thresholds may vary since the threshold is also

affected by factors such as the tolerances of the

thermistor and/or other components, load

resistor value, test conditions, and heat

generation inside the detector enclosure. As a

Figure 9 - Expected performance of methane detectors

with classified TGS2611 & recommended R

L

for 10% LEL

(

refer to Table 3 for test conditions

)

d

n

a

e

r

u

t

a

r

e

p

m

e

T

y

t

i

d

i

m

u

h

d

r

a

d

n

a

t

S

s

n

o

i

t

i

d

n

o

c

0

2

±

5

6

,

C

˚

2

±

H

R

%

5

g

n

i

t

a

r

e

p

O

s

n

o

i

t

i

d

n

o

c

H

R

%

5

9

~

0

3

,

C

˚

0

4

~

0

1

-

t

i

u

c

r

i

C

n

o

i

t

i

d

n

o

c

d

r

a

d

n

a

t

S

s

n

o

i

t

i

d

n

o

c

0

.

5

=

c

V

±

C

D

V

1

0

.

0

0

.

5

=

H

V

±

C

D

V

5

0

.

0

g

n

i

t

a

r

e

p

O

s

n

o

i

t

i

d

n

o

c

0

.

5

=

c

V

±

C

D

V

2

.

0

0

.

5

=

H

V

±

C

D

V

2

.

0

r

o

i

r

p

g

n

i

n

o

i

t

i

d

n

o

C

t

s

e

t

o

t

≥

s

r

u

o

h

8

4

Table 3 - Test conditions for measuring

performance of methane detectors as shown in Figure 9

3

4

5

6

7

8

9 10

20

15

30

under std

test conditions

under operating conditions

at recommended circuit condition

Alarming point (%LEL)

25