MR25664

15

MAINTENANCE

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation. Maintenance requirements

have been reduced to the absolute minimum. However, it is very important that these maintenance

functions be performed as described below.

WARNING!

Failure to obey the following procedures could result in death or serious injury.

•

Never walk under or climb on raised liftarms or a raised attachment.

•

Do not use blocking made of concrete blocks, logs, buckets, barrels or

any other material that cold suddenly collapse or shift positions. Do not

use wood or steel blocking that shows any signs of material decay. Do

not use blocking that is warped, twisted, or tapered.

•

If the attachment must be raised, block the machine with blocks or

jackstands, NOT lift jacks or hoists. Always block the rear wheels of the

Planer in a manner that stabilizes the chassis.

•

Always wear protective equipment including a HARD HAT and EYE

PROTECTION when operating, performing maintenance, or working near

this

product.

•

The Attachment Part group and the Chassis Part group pivot freely. Do

not place any part of your body between these areas or under this

product without stabilizing this pivot point.

ANNUALLY

NOTE: Initial oil change should be after 50 hours of operation. Subsequent oil change should be

every 1000 hours of operation or annually, whichever comes first.

Planetary gearbox is to be half full of oil when the unit is mounted level and horizontal. Use

mild extreme pressure lubricant API-GL-5, No. 80 or 90. The capacity of the gearbox is 30

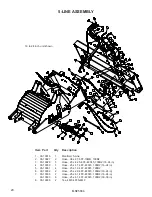

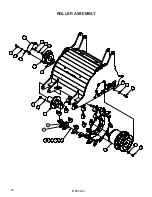

oz. Refer to Parts Illustrations to disassemble and reassemble your Planer.

To change the oil in the Planetary Gearbox:

1.

Remove motor. NOTE: motor shaft adapter is loose and can fall from planetary.

2.

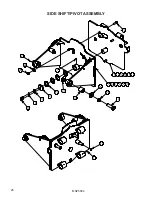

Remove pivot weldment with attach weldment. Keep attach weldment close and do not stretch

hoses.

3.

Remove depth cylinders. Hydraulic lines can be left attached.

4.

Remove two depth skids.

5.

Remove the right and left support plates from the chassis.

6.

Using the lift point on the chassis, raise the chassis off of the drum.

7.

Remove the planetary.

8.

Remove drain plug from the planetary.

9.

Drain oil from planetary.

10.

Fill planetary with oil. The oil level must be at the bottom of the threads with the hole level. Do

not tip the planetary, as the oil can run out of the planetary before the motor is installed.

11.

Clean any debris from the drain plug and apply pipe thread sealant to the threads.

12.

Install the planetary in the drum.

13.

Install the drum in the chassis. Install the depth skids, pivot weldment, and depth cylinders.

14.

Complete the reassembly of your Planer. (See Parts Illustrations & Parts Lists and Torque

Specifications for reference during reassembly.)