9

Eccentric motion (fi ne sanding)

This position is selected for sanding with

low output for a scratch-free surface

(fi ne sanding).

Press the switch (1.1) downwards and push it

into the left-hand position.

5.2 Sanding

pad

brake

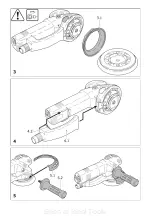

The rubber collar (3.1) prevents the sanding

pad from revving up to maximum speed in an

uncontrolled manner during eccentric motion

(fi ne sanding). Because the collar wears down

in the course of time, it has to be replaced by a

new one (order no. 465 472) as soon as there

is any reduction in the braking effect.

5.3

Choice and installation of the san-

ding disks

Choise of sanding disk

The appliance can be fi tted with three sanding

disks of different hardness depending on the

surface to be treated.

Hard:

coarse sanding on surfaces, sanding at

edges.

Soft:

universal for coarse and fi ne sanding for

fl at and curved surfaces.

Super-soft:

fi ne sanding on formed parts,

curves, radii. Do not use on edges!

Assembly

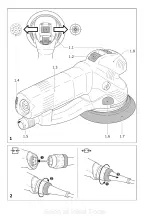

The FastFix system enables tool-free replace-

ment of the sanding pad:

- Set the switch (1.1) to the right, to the Rotex

rotary motion

- Press spindle stop (1.6), direction of move-

ment (3.2) fi rst to the side, then forwards

- Turn the fi tted sanding pad from the spindle

(right-handed thread)

- Keep the spindle stop pressed and screw

on the new sanding pad (in doing so, make

sure that the rubber collar (3.1) is correctly

fi tted!)

- let go of the spindle stop

Actuate the spindle stop only when the drive

spindle is stationary. Do not switch on the motor

when the spindle stop is pressed in.

5.4 Attaching

sanding

material

The appropriate Stickfi x sanding paper and

Stickfi x sanding felt can be fastened quickly and

easily onto the Stickfi x sanding base.

The self-adhesive sanding material is simply

pressed onto the sanding base (1.7) and held

safely in place by the Stickfi x sanding base vel-

cro surface. After use, the StickFix sandpaper

is simply pulled off.

5.5 Securing

polishing

attachments

To prevent damage, PoliStick polishing attach-

ments (sponges, felt, lambswool bonnets) may

only be used on the special polishing pad that

is fi tted on the machine instead of a sanding

pad. In the same way as the StickFix abrasives,

the PoliStick polishing attachments are simply

pressed onto the polishing pad and pulled off

after use.

5.6 Dust

extraction

Always connect the machine to a dust

extractor.

You can connect a Festool extractor with an ex-

tractor hose diameter of 27 mm to the extractor

connector (1.5). The extraction adapter (4.1)

can be removed if necessary. To do this, press

the locking button (4.2), draw the extraction

adapter backwards and pull off. To reattach the

extraction adapter, insert it as shown in Fig. 4

and slide it towards the sanding pad until the

locking button (4.2) latches into place.

5.7 Edge

protector

The edge protector (5.1) prevents the sanding

pad from touching the edge perpendicular to a

surface (e.g. when sanding along a wall), there-

by preventing the machine from rebounding.

Assembly

Slide the edge protector onto the machine until

it latches into place (see Fig. 5).

5.8 Auxiliary

handle

The auxiliary handle (Accessories, 5.2) can

be screwed onto either the right or left of the

gear head.

6

Working with the machine

Always secure the workpiece in such a

manner that it cannot move while being

sawed.

For safe guidance, hold the machine with both

hands on the motor housing (1.3) and on the

gear head (1.8) and/or the auxiliary handle

(Accessories, 5.2).

Never overload the tool by using too much

pressure! The best sanding results are achieved

when applying moderate pressure. The sanding

performance and quality depend mainly on the

choice of the right sanding material.

Tables A and B show the settings we recommend

for different sanding and polishing work.

6.1 Metalworking

The following precautions are to be ta-

ken when processing metals for safety

reasons:

- Pre-connect a residual current circuit-breaker

(FI, PRCD).

- Connect the machine to a suitable dust ex-

tractor.

- Clean tool regularly of dust accumulations in

the motor housing.

- Wear protective goggles.

7 Accessories,

tools

For your own safety, use only original

Festool accessories and spare parts.

Festool offers the appropriate accessories,

sanding and polishing attachments for every

application.

Seen at Ideal Tools.

Summary of Contents for ROTEX RO 150 FEQ

Page 2: ...Seen at Ideal Tools ...

Page 3: ...Seen at Ideal Tools ...