16

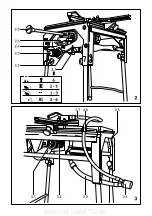

Press spindle stop (5.2 - behind saw blade) and

rotate saw shaft with hexagon key until button (5.2)

catches and locks the saw shaft.

Attention:

the saw blade locking screw has a left-

hand thread.

Release locking screw by turning firmly to the right

and remove clamping flange and saw blade. Insert

new saw blade.

Attention:

Pay attention to the direction of rotation

(cutting edge of saw teeth in direction of rotation

(5.4))! Screw saw blade and flange to saw shaft

with locking screw.

Close the cover (5.10) and replace the upper

protective hood again.

Warning

: Make sure that the cover (5.10) engages

in the clips (5.9) when closing.

Return hexagon key to holder and replace table inlay

in table.

First insert the inlay into the front of the table frame

with protruding spring steel sheet (5.5).

Insert inlay and screw tight with claw and rotary

knob.

13 Maintenance and service

13.1 Removing dust accumulations

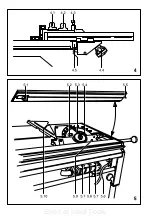

General accumulations of dust are to be sucked

off with a dust extractor from time to time.

We especially recommend:

a)

cleaning the gears behind the rotary knob

(2.3)

b)

leaning the two guide rods after tilting the saw

onto one side.

13.2 Cleaning the filter (only CS 70 EB)

If the cut-out cycles of the temperature monitoring

system in accordance with section 6.4 become

shorter with no extreme overload, the air intake filter

(3.2) should be cleaned.

Release rotary knob (3.1), remove filter insert and

remove dust by tapping on the front or vacuuming

the surface of the filter. Replace filter.

Exchange any damaged filter with a new filter

cartridge (order no. 447 995).

13.3 Inspection and servicing

The device is fitted with special motor brushes with

an automatic cut-out.

When the brushes become worn the power supply

is shut off automatically and the tool comes to a

standstill.

If this occurs, the machine should be returned to a

Festool customer service workshop or specialised

workshop to change the brushes.

The specialised workshop can order repair

instructions from Festool under the order

no. 450 157 to carry out the following simple

repairs: change brushes, change the belt, replace

the electronics, clean the scraper on the guides,

change the mains cable, replace the motor, replace

the switch.

Any maintenance and repair work requiring an

opening of the drive unit and electrical system may

only be carried out by a Festool customer service

workshop or specialised workshop.

14 Range of accessories

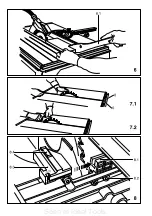

14.1 Extension table

The CS 70 VB extension table (order no. 488 060)

can be fitted to the basic table of the PRECISIO for

safe and precise sawing to width (with stop) up to

a cutting width of 680 mm.

14.2 Extension table

The extension table CS 70 VL (order no. 488 061)

is available for fitting to the basic table for safe

sawing of longer workpieces.

14.3 Linear stop

The linear stop CS 70 LA (order no. 488 062) is

indispensable for safe and precise linear cuts.

14.4 Switch cover

If the switch cover CS 70 SA order no. 488 065) is

fitted, the machine can be protected against

unauthorised use with a padlock.

14.5 Transportation rollers

Transportation rollers CS 70 TR (order no. 488 064)

can be fitted to the foldaway legs of the saw to

enable simple and easy transportation.

14.6 Sliding platform

The sliding platform CS 70 ST (order no. 488 059)

can be fitted to the PRECISIO when sawing boards

up to a cutting length of 920 mm.

The sliding platform CS 70 ST 650 (order no.

490 312) can be fitted to the PRECISIO when

sawing boards up to a cutting length of 650 mm.

14.7 Saw blades

HM Ø 225 x 2.5 x Ø 30

Universal HW / 32

Order no. 488 288

Fine-tooth HW / 48

Order no. 488 289

Panther HW / 18

Order no. 488 290

Special HW / 68

Order no. 488 291

Seen at Ideal Tools.

Summary of Contents for Precisio CS 70 E

Page 2: ...Seen at Ideal Tools ...

Page 3: ...Seen at Ideal Tools ...

Page 4: ...Seen at Ideal Tools ...

Page 5: ...Seen at Ideal Tools ...